Description:

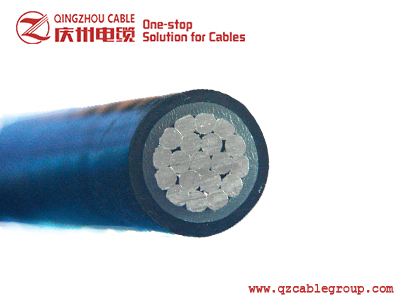

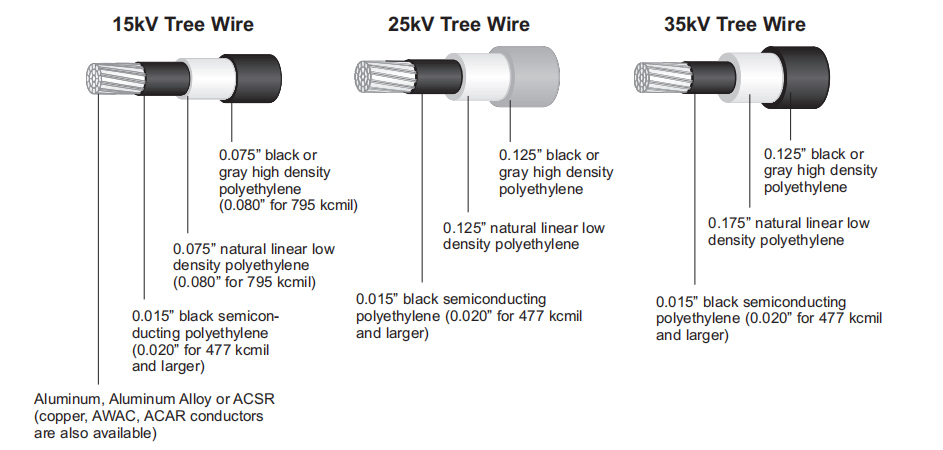

Tree wire or covered open wire consists of the conductor (aluminum, aluminum alloy or ACSR ) and the extruded covering (conductor shield, low density inner layer and protective outer layer). Covering thickness depends on the system voltage. It is designed for full span applications and is supported on polyethylene insulators. We also offer a two layer covered conductor design for 15kV systems that are not subject to heavy tree contact. Covered conductors are available in black or gray depending on visual preference.

Used for primary and secondary overhead distribution where limited space is available or desired for rights-of-way. Installed the same as bare conductors, however, covering is effective in preventing direct shorts and instantaneous flash overs should tree limbs or other objects contact conductors in such close proximity.

Tree Wire – Used for spans where trees crowd the right-of-way, such as in wooded residential areas, when a minimum of interference with the environment is desired. Covering minimizes power outages due to conductor contact with tree limbs, reducing the need for frequent or severe trimming.

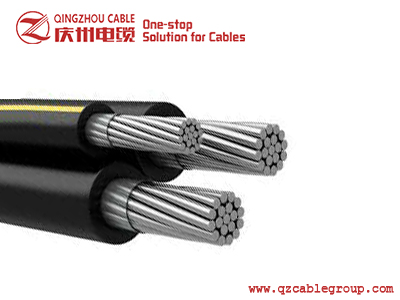

Covered Aerial MV Cable – Installed with other Covered Aerial MV cables and a supporting messenger through a series of space- maintaining devices (spacers). The resulting close-proximity configuration minimizes the amount of space and hardware required for line installation, particularly useful in congested areas.

Spacer Cable – Installed with other spacer cables and a supporting messenger through a series of space-maintaining devices (spacers). The resulting close-proximity configuration minimizes the amount of space and hardware required for line installation; particularly useful in congested areas.

Benefits:

Covering prevents faults due to contact

Proprietary, high density outer layer resists abrasion, electrical tracking and UV degradation.

Reduced NESC phase spacing is possible due to high impulse strength covering.

Pole hardware is the same as bare wire construction except that Hendrix polyethylene insulators are required.

Application:

Qingzhou Cable provides tree wire designed for systems from 15kV through 46kV. Polyethylene insulators must be used to insure dielectric compatibility with conductor covering. Conductors are supported on crossarms or standoff brackets. Span lengths are limited by the conductor breaking strength and the amount of sag that is permissible. Covered conductors are rated for continuous operation at 75°C. (Consult sales representative for 46kV tree wire systems).

IEC BS EN 50397 Standard 15kv 25kv 35kv Overhead Covered Conductor

|

15kv Overhead Covered Conductor |

|||||||

|

Cross section |

No. of wires |

Conductor dia. |

Overall Diameter |

Minimum breaking load |

Approx. weight |

Max. DC-resistance at 20°C |

Ampacity 90°C |

|

[mm²] |

|

[mm] |

[mm] |

[kgf] |

[kg/km] |

[Ohm/km] |

[A] |

|

35 |

7 |

7.1 |

13.6 |

464 |

190 |

0.868 |

187 |

|

50 |

7 |

8.2 |

14.7 |

663 |

235 |

0.641 |

225 |

|

70 |

19 |

9.7 |

16.2 |

928 |

315 |

0.443 |

282 |

|

95 |

19 |

11.5 |

18 |

1259 |

400 |

0.32 |

345 |

|

120 |

19 |

12.9 |

19.4 |

1591 |

500 |

0.253 |

401 |

|

150 |

19 |

14.2 |

20.7 |

1988 |

580 |

0.206 |

456 |

|

185 |

37 |

16.2 |

22.6 |

2452 |

695 |

0.164 |

525 |

|

240 |

37 |

18.4 |

24.9 |

3182 |

875 |

0.125 |

625 |

|

300 |

37 |

20.7 |

27.1 |

3977 |

1070 |

0.1 |

721 |

|

25kv Overhead Covered Conductor |

|||||||

|

Cross section |

No. of wires |

Conductor dia. |

Overall Diameter |

Minimum breaking load |

Approx. weight |

Max. DC-resistance at 20°C |

Ampacity 90°C |

|

[mm²] |

|

[mm] |

[mm] |

[kgf] |

[kg/km] |

[Ohm/km] |

[A] |

|

35 |

7 |

7.1 |

15.7 |

464 |

235 |

0.868 |

186 |

|

50 |

7 |

8.2 |

16.8 |

663 |

305 |

0.641 |

224 |

|

70 |

19 |

9.7 |

18.3 |

928 |

370 |

0.443 |

280 |

|

95 |

19 |

11.5 |

20.1 |

1259 |

460 |

0.32 |

343 |

|

120 |

19 |

12.9 |

21.5 |

1591 |

560 |

0.253 |

397 |

|

150 |

19 |

14.2 |

22.8 |

1988 |

650 |

0.206 |

450 |

|

185 |

37 |

16.2 |

24.8 |

2452 |

770 |

0.164 |

519 |

|

240 |

37 |

18.4 |

27 |

3182 |

960 |

0.125 |

617 |

|

300 |

37 |

20.7 |

29.3 |

3977 |

1155 |

0.1 |

712 |

|

35kv Overhead Covered Conductor |

|||||||

|

Cross section |

No. of wires |

Conductor dia. |

Overall Diameter |

Minimum breaking load |

Approx. weight |

Max. DC-resistance at 20°C |

Ampacity 90°C |

|

[mm²] |

|

[mm] |

[mm] |

[kgf] |

[kg/km] |

[Ohm/km] |

[A] |

|

70 |

19 |

9.7 |

25.7 |

928 |

620 |

0.443 |

270 |

|

95 |

19 |

11.5 |

27.5 |

1259 |

732 |

0.32 |

329 |

|

120 |

19 |

12.9 |

28.9 |

1591 |

830 |

0.253 |

381 |

|

150 |

19 |

14.2 |

30.2 |

1988 |

937 |

0.206 |

432 |

|

185 |

37 |

16.2 |

32.2 |

2452 |

1083 |

0.164 |

497 |

|

240 |

37 |

18.4 |

34.4 |

3182 |

1290 |

0.125 |

589 |

|

300 |

37 |

20.7 |

36.7 |

3977 |

1502 |

0.1 |

674 |

Australia Standard MV 6.35/11kv 12.7/22kV CCT Overhead Covered Conductor, Aerial Cables. AS/NZS 3675

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

|

|

Conductor size No./mm |

Conductor d.c. resistance at 20°C Ω/km |

Conductor a.c. resistance at 80°C Ω/km |

Reactance at 50 Hz (460 mm spacing) Ω/km |

Continuous current carrying capacity |

Fault current rating kA for 1 sec.* |

Everday working tensionf kN |

Maximum working tension (50% MBL) kN |

Minimum breaking load kN |

Minimum bending radius mm |

||||||

|

Based on 30°C ambient |

Based on 40°C ambient |

||||||||||||||

|

Still air |

1.0 m/s wind |

2.0 m/s wind |

Still air |

1.0 m/s wind |

2.0 m/s wind |

||||||||||

|

Alloy 6201 |

|||||||||||||||

|

7/2.75 |

0.799 |

0.988 |

0.331 |

125 |

210 |

235 |

110 |

185 |

210 |

3.5 |

1.51 |

5.80 |

11.6 |

200 |

|

|

7/3.75 |

0.430 |

0.532 |

0.312 |

180 |

300 |

345 |

160 |

270 |

310 |

6.4 |

2.82 |

10.90 |

21.7 |

245 |

|

|

7/4.75 |

0.268 |

0.331 |

0.297 |

245 |

410 |

465 |

220 |

365 |

415 |

10.3 |

4.52 |

17.40 |

34.8 |

290 |

|

|

19/3.50 |

0.183 |

0.227 |

0.281 |

315 |

515 |

595 |

280 |

460 |

530 |

15.2 |

6.67 |

25.70 |

51.3 |

340 |

|

|

Alloy 1120 |

|||||||||||||||

|

7/2.75 |

0.713 |

0.881 |

0.331 |

130 |

220 |

250 |

115 |

195 |

225 |

3.7 |

1.49 |

4.96 |

9.91 |

200 |

|

|

7/3.75 |

0.383 |

0.474 |

0.312 |

190 |

320 |

365 |

170 |

285 |

325 |

6.8 |

2.64 |

8.80 |

17.60 |

245 |

|

|

7/4.75 |

0.239 |

0.296 |

0.297 |

260 |

430 |

485 |

230 |

385 |

435 |

11.0 |

4.07 |

13.60 |

27.10 |

290 |

|

|

19/3.50 |

0.163 |

0.202 |

0.281 |

330 |

545 |

625 |

295 |

485 |

560 |

16.2 |

6.26 |

20.90 |

41.70 |

340 |

|

|

TECHNICAL PERFORMANCE CHARACTERISTICS FOR COVERED CONDUCTORS (CCT) |

|||||||||||||||

|

Conductor size No./mm |

Conductor d.c. resistance at 20°C Ω/km |

Conductor a.c. resistance at 80°C Ω/km |

Reactance at 50 Hz (460 mm spacing) Ω/km |

Continuous current carrying capacity |

Fault current rating kA for 1 sec.* |

Everday working tensionf kN |

Maximum working tension (50% MBL) kN |

Minimum breaking load kN |

Minimum bending radius mm |

||||||

|

Based on 30°C ambient |

Based on 40°C ambient

|

||||||||||||||

|

Still air |

1.0 m/s wind |

2.0 m/s wind |

Still air |

1.0 m/s wind |

2.0 m/s wind |

||||||||||

|

11 kV Alloy 6201 |

|||||||||||||||

|

7/3.75 |

0.430 |

0.532 |

0.312 |

185 |

295 |

330 |

165 |

265 |

295 |

6.4 |

2.82 |

10.9 |

21.7 |

285 |

|

|

7/4.75 |

0.268 |

0.331 |

0.297 |

245 |

390 |

440 |

220 |

350 |

395 |

10.3 |

4.52 |

17.4 |

34.8 |

330 |

|

|

19/3.50 |

0.183 |

0.227 |

0.281 |

315 |

500 |

560 |

280 |

445 |

500 |

15.2 |

6.67 |

25.7 |

51.3 |

380 |

|

|

22 kV Alloy 6201 |

|||||||||||||||

|

7/3.75 |

0.430 |

0.532 |

0.312 |

185 |

285 |

315 |

165 |

255 |

280 |

6.4 |

2.82 |

10.9 |

21.7 |

350 |

|

|

7/4.75 |

0.268 |

0.331 |

0.297 |

245 |

375 |

420 |

220 |

335 |

375 |

10.3 |

4.52 |

17.4 |

34.8 |

395 |

|

|

19/3.50 |

0.183 |

0.227 |

0.281 |

315 |

475 |

530 |

280 |

425 |

475 |

15.2 |

6.67 |

25.7 |

51.3 |

445 |

|

|

33 kV Alloy 6201 |

|||||||||||||||

|

7/3.75 |

0.430 |

0.532 |

0.312 |

185 |

270 |

295 |

165 |

240 |

265 |

6.4 |

2.82 |

10.9 |

21.7 |

425 |

|

|

7/4.75 |

0.268 |

0.331 |

0.297 |

245 |

360 |

400 |

220 |

320 |

355 |

10.3 |

4.52 |

17.4 |

34.8 |

470 |

|

|

19/3.50 |

0.183 |

0.227 |

0.281 |

315 |

455 |

505 |

280 |

405 |

450 |

15.2 |

6.67 |

25.7 |

51.3 |

520 |

|

|

XLPE covered aerial cables Alloy 1120 conductors |

|||||||||||||||

|

Conductor size No./mm |

Conductor d.c. resistance at 20°C Ω/km |

Conductor a.c. resistance at 80°C Ω/km |

Reactance at 50 Hz (460 mm spacing) Ω/km |

Continuous current carrying capacity |

Fault current rating kA for 1 sec.* |

Everday working tensionf kN |

Maximum working tension (50% MBL) kN |

Minimum breaking load kN |

Minimum bending radius mm |

||||||

|

Based on 30°C ambient |

Based on 40°C ambient |

||||||||||||||

|

Still air |

1.0 m/s wind |

2.0 m/s wind |

Still air |

1.0 m/s wind |

2.0 m/s wind |

||||||||||

|

11 kV Alloy 1120 |

|||||||||||||||

|

7/2.75 |

0.713 |

0.881 |

0.331 |

130 |

215 |

240 |

115 |

190 |

215 |

3.7 |

1.49 |

4.96 |

9.9 |

230 |

|

|

7/3.75 |

0.383 |

0.474 |

0.312 |

190 |

315 |

345 |

170 |

280 |

310 |

6.8 |

2.64 |

8.80 |

17.6 |

285 |

|

|

7/4.75 |

0.239 |

0.296 |

0.297 |

26() |

415 |

470 |

230 |

370 |

420 |

11.0 |

4.07 |

13.6 |

27.1 |

330 |

|

|

19/3.50 |

0.163 |

0.202 |

0.281 |

330 |

525 |

595 |

295 |

470 |

530 |

16.2 |

6.26 |

20.9 |

41.7 |

380 |

|

|

22 kV Alloy 1120 |

|||||||||||||||

|

7/2.75 |

0.713 |

0.881 |

0.331 |

135 |

205 |

225 |

120 |

185 |

200 |

3.7 |

1.49 |

4.96 |

9.9 |

300 |

|

|

7/3.75 |

0.383 |

0.474 |

0.312 |

190 |

295 |

330 |

170 |

265 |

295 |

6.8 |

2.64 |

8.80 |

17.6 |

350 |

|

|

7/4.75 |

0.239 |

0.296 |

0.297 |

260 |

400 |

440 |

230 |

355 |

395 |

11.0 |

4.07 |

13.6 |

27.1 |

395 |

|

|

19/3.50 |

0.163 |

0.202 |

0.281 |

330 |

505 |

560 |

295 |

450 |

500 |

16.2 |

6.26 |

20.9 |

41.7 |

445 |

|

|

33 kV Alloy 1120 |

|||||||||||||||

|

7/2.75 |

0.713 |

0.881 |

0.331 |

135 |

195 |

215 |

120 |

175 |

190 |

3.7 |

1.49 |

4.96 |

9.9 |

385 |

|

|

7/3.75 |

0.383 |

0.474 |

0.312 |

195 |

285 |

315 |

175 |

255 |

280 |

6.8 |

2.64 |

8.80 |

17.6 |

425 |

|

|

7/4.75 |

0.239 |

0.296 |

0.297 |

260 |

380 |

420 |

230 |

340 |

375 |

11.0 |

4.07 |

13.6 |

27.1 |

470 |

|

|

19/3.50 |

0.163 |

0.202 |

0.281 |

330 |

480 |

530 |

295 |

430 |

475 |

16.2 |

6.26 |

20.9 |

41.7 |

520 |

|

|

* Initial temperature 80°C, final temperature 210°C, constant K = 83.0 for alloy 6201 and 88.4 for alloy 1120. f 13% MBL fbr alloy 6201 and 15% MBL for alloy 1120. |

|||||||||||||||

American Standard One Two Three Layer MV 5kv 15KV 25KV 35KV Overhead Covered Conductor.

|

One-Layer 5kv AAC Tree Wire (All-Aluminum Conductors) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Size (AWG or kcmil) |

Stranding |

Cover Thickness (mils) |

Cable O.D.+ (mils) |

Rated Strenght (lbs) |

Weight per 1000 ft. (lbs) |

Allowable Ampacity* |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

XLP |

HD Poly |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

7 |

80 |

385 |

793 |

72 |

73 |

135 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

7 |

80 |

443 |

1210 |

102 |

104 |

180 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

19 |

80 |

482 |

1570 |

121 |

123 |

210 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

19 |

80 |

522 |

1940 |

146 |

148 |

240 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

19 |

80 |

565 |

2400 |

176 |

179 |

275 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

19 |

80 |

616 |

2980 |

215 |

218 |

320 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

19 |

80 |

672 |

3620 |

263 |

266 |

370 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

250 |

37 |

80 |

718 |

4420 |

300 |

304 |

410 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

80 |

734 |

4470 |

322 |

325 |

425 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

300 |

37 |

80 |

771 |

5300 |

353 |

356 |

455 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

37 |

80 |

807 |

5790 |

391 |

395 |

490 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

350 |

37 |

80 |

821 |

6080 |

406 |

409 |

505 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

37 |

80 |

931 |

7820 |

536 |

541 |

610 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

500 |

37 |

80 |

950 |

8200 |

560 |

565 |

625 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

One-Layer 5kv ACSR Tree Wire (Aluminum Conductor Steel Reinforced) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

6/1 |

80 |

410 |

1770 |

94 |

96 |

135 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

6/1 |

80 |

476 |

2710 |

137 |

139 |

180 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

6/1 |

80 |

514 |

3370 |

166 |

168 |

205 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

80 |

558 |

4160 |

202 |

205 |

230 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

80 |

607 |

5040 |

247 |

250 |

265 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

6/1 |

80 |

662 |

6290 |

303 |

307 |

305 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

80 |

723 |

7930 |

374 |

378 |

345 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

80 |

769 |

6540 |

372 |

376 |

430 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

80 |

802 |

10700 |

449 |

453 |

440 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

80 |

844 |

8250 |

458 |

463 |

500 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

80 |

880 |

13400 |

555 |

559 |

510 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

80 |

903 |

9440 |

534 |

539 |

555 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

80 |

943 |

15500 |

647 |

652 |

565 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

18/1 |

80 |

974 |

11200 |

631 |

637 |

620 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

80 |

1018 |

185000 |

767 |

773 |

630 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

One-Layer 15kv AAC Tree Wire (All-Aluminum Conductors) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

7 |

150 |

525 |

793 |

114 |

115 |

135 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

7 |

150 |

583 |

1210 |

150 |

151 |

175 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

19 |

150 |

622 |

1570 |

172 |

173 |

205 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

19 |

150 |

662 |

1940 |

— |

202 |

235 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

19 |

150 |

705 |

2400 |

236 |

237 |

270 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

19 |

150 |

756 |

2980 |

279 |

281 |

310 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

19 |

150 |

812 |

3620 |

333 |

334 |

355 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

150 |

874 |

4470 |

397 |

399 |

410 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

300 |

37 |

150 |

911 |

5300 |

432 |

433 |

440 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

37 |

150 |

947 |

5790 |

473 |

475 |

475 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

350 |

37 |

150 |

961 |

6080 |

489 |

491 |

485 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

37 |

150 |

1071 |

7820 |

631 |

633 |

585 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

500 |

37 |

150 |

1090 |

8200 |

656 |

658 |

605 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

One-Layer 15kv ACSR Tree Wire (Aluminum Conductor Steel Reinforced) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

6/1 |

150 |

550 |

1770 |

139 |

140 |

135 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

6/1 |

150 |

616 |

2710 |

188 |

189 |

175 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

6/1 |

150 |

654 |

3370 |

221 |

222 |

200 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

150 |

698 |

4160 |

261 |

263 |

230 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

150 |

747 |

5040 |

— |

312 |

260 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

6/1 |

150 |

802 |

6290 |

372 |

374 |

295 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

150 |

863 |

7930 |

449 |

450 |

330 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

150 |

909 |

6540 |

451 |

453 |

415 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

150 |

942 |

10700 |

531 |

533 |

425 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

150 |

984 |

8250 |

545 |

547 |

480 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

150 |

1020 |

13400 |

645 |

647 |

490 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

150 |

1043 |

9440 |

626 |

628 |

535 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

150 |

1083 |

15500 |

743 |

745 |

545 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

18/1 |

150 |

1114 |

11200 |

730 |

733 |

595 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

150 |

1158 |

18500 |

870 |

872 |

610 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2-Layer 15kV ACSR Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

6/1 |

250 |

75 |

75 |

550 |

1767 |

136 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

6/1 |

316 |

75 |

75 |

616 |

2708 |

184 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

398 |

75 |

75 |

698 |

4161 |

255 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

447 |

75 |

75 |

747 |

5045 |

303 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

6/1 |

502 |

75 |

75 |

802 |

6289 |

362 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

563 |

75 |

75 |

863 |

7933 |

432 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

609 |

75 |

75 |

909 |

6536 |

441 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

642 |

75 |

75 |

942 |

10735 |

452 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

684 |

75 |

75 |

984 |

8246 |

536 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

720 |

75 |

75 |

1020 |

13395 |

555 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

30/7 |

741 |

75 |

75 |

1041 |

16435 |

621 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

743 |

75 |

75 |

1043 |

9443 |

611 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

24/7 |

772 |

75 |

75 |

1072 |

13870 |

609 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

783 |

75 |

75 |

1083 |

1545 |

645 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

24/7 |

846 |

75 |

75 |

1146 |

16340 |

719 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

858 |

75 |

75 |

1158 |

18525 |

762 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

30/7 |

883 |

75 |

75 |

1183 |

22610 |

854 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

18/1 |

879 |

75 |

75 |

1179 |

13015 |

813 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

24/7 |

914 |

75 |

75 |

1214 |

18810 |

828 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

26/7 |

927 |

75 |

75 |

1227 |

21470 |

878 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

18/1 |

940 |

75 |

75 |

1240 |

14915 |

912 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

24/7 |

977 |

75 |

75 |

1277 |

20900 |

936 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

26/7 |

990 |

75 |

75 |

1290 |

23940 |

993 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

26/7 |

1108 |

80 |

80 |

1428 |

29925 |

1234 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

45/7 |

1063 |

80 |

80 |

1383 |

20995 |

1031 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2-Layer 15kV AAAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

48.69 |

4 |

7 |

250 |

75 |

75 |

550 |

1584 |

124 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

77.47 |

2 |

7 |

316 |

75 |

75 |

616 |

2520 |

165 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

123.3 |

1/0 |

7 |

398 |

75 |

75 |

698 |

4014 |

225 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

155.4 |

2/0 |

7 |

447 |

75 |

75 |

747 |

4851 |

265 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

195.7 |

3/0 |

7 |

502 |

75 |

75 |

802 |

6111 |

314 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

246.9 |

4/0 |

7 |

563 |

75 |

75 |

863 |

7704 |

376 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

312.8 |

266.8 |

19 |

642 |

75 |

75 |

942 |

9900 |

450 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

394.5 |

336.4 |

19 |

720 |

75 |

75 |

1020 |

11970 |

543 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

465.4 |

397.5 |

19 |

782 |

75 |

75 |

1082 |

14040 |

623 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

559.5 |

477 |

19 |

858 |

75 |

75 |

1158 |

16920 |

727 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

652.4 |

556.5 |

19 |

927 |

75 |

75 |

1227 |

19710 |

828 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

740.8 |

636 |

37 |

990 |

80 |

80 |

1310 |

21960 |

938 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2-Layer 15kV AAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

7 |

336 |

75 |

75 |

636 |

1791 |

196 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

7 |

376 |

75 |

75 |

676 |

2259 |

230 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

7 |

423 |

75 |

75 |

723 |

2736 |

272 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

7 |

475 |

75 |

75 |

775 |

3447 |

325 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

537 |

75 |

75 |

837 |

4473 |

387 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

19 |

603 |

75 |

75 |

903 |

5535 |

466 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

19 |

659 |

75 |

75 |

959 |

6399 |

535 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

19 |

722 |

75 |

75 |

1022 |

7524 |

623 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

37 |

780 |

75 |

75 |

1080 |

8946 |

708 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

37 |

835 |

75 |

75 |

1135 |

10260 |

794 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 15kV ACSR Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Size (AWG or kcmil) |

Stranding |

Conductor Diameter (mils) |

Covering Thickness (mils) |

Cable O.D. (mils) |

Rated Strength (lbs) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Conductor Shield |

Inner Layer |

Outer Layer |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

6/1 |

250 |

15 |

75 |

75 |

580 |

1767 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

6/1 |

316 |

15 |

75 |

75 |

646 |

2708 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

398 |

15 |

75 |

75 |

728 |

4161 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

447 |

15 |

75 |

75 |

777 |

5045 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

6/1 |

502 |

15 |

75 |

75 |

832 |

6289 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

563 |

15 |

75 |

75 |

893 |

7933 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

609 |

15 |

75 |

75 |

939 |

6536 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

642 |

15 |

75 |

75 |

972 |

10735 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

684 |

15 |

75 |

75 |

1014 |

8246 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

720 |

15 |

75 |

75 |

1050 |

13395 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

30/7 |

741 |

15 |

75 |

75 |

1071 |

16435 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

743 |

15 |

75 |

75 |

1073 |

9443 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

24/7 |

772 |

15 |

75 |

75 |

1102 |

13870 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

783 |

15 |

75 |

75 |

1113 |

15485 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

24/7 |

846 |

15 |

75 |

75 |

1176 |

16340 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

858 |

15 |

75 |

75 |

1188 |

18525 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

30/7 |

883 |

15 |

75 |

75 |

1213 |

22610 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

18/1 |

879 |

20 |

75 |

75 |

1219 |

13015 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

24/7 |

914 |

20 |

75 |

75 |

1254 |

18810 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

26/7 |

927 |

20 |

75 |

75 |

1267 |

21470 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

18/1 |

940 |

20 |

75 |

75 |

1280 |

14915 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

26/7 |

990 |

20 |

75 |

75 |

1330 |

23940 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 15kV AAAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

48.69 |

4 |

7 |

250 |

15 |

75 |

75 |

580 |

1584 |

137 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

77.47 |

2 |

7 |

316 |

15 |

75 |

75 |

646 |

2520 |

179 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

123.3 |

1/0 |

7 |

398 |

15 |

75 |

75 |

728 |

4014 |

241 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

155.4 |

2/0 |

7 |

447 |

15 |

75 |

75 |

777 |

4851 |

283 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

195.7 |

3/0 |

7 |

502 |

15 |

75 |

75 |

832 |

6111 |

334 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

246.9 |

4/0 |

7 |

563 |

15 |

75 |

75 |

893 |

7704 |

397 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

312.8 |

266.8 |

19 |

642 |

15 |

75 |

75 |

972 |

9900 |

473 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

394.5 |

336.4 |

19 |

720 |

15 |

75 |

75 |

1050 |

11970 |

568 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

465.4 |

397.5 |

19 |

783 |

15 |

75 |

75 |

1113 |

14040 |

649 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

559.5 |

477 |

19 |

858 |

15 |

75 |

75 |

1188 |

16920 |

755 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

652.4 |

556.5 |

19 |

927 |

20 |

75 |

75 |

1267 |

19710 |

894 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

740.8 |

636 |

37 |

990 |

20 |

75 |

75 |

1330 |

21960 |

963 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 15kV AAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

7 |

336 |

15 |

75 |

75 |

666 |

1791 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

7 |

376 |

15 |

75 |

75 |

706 |

2259 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

7 |

423 |

15 |

75 |

75 |

753 |

2736 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

7 |

475 |

15 |

75 |

75 |

805 |

3447 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

537 |

15 |

75 |

75 |

867 |

4473 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

19 |

603 |

15 |

75 |

75 |

933 |

5535 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

19 |

659 |

15 |

75 |

75 |

989 |

6399 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

19 |

722 |

15 |

75 |

75 |

1052 |

7524 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

37 |

780 |

20 |

75 |

75 |

1120 |

8946 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

37 |

835 |

20 |

80 |

80 |

1195 |

10260 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

37 |

932 |

20 |

80 |

80 |

1292 |

12510 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 25kV ACSR Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

398 |

15 |

125 |

125 |

928 |

4161 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

447 |

15 |

125 |

125 |

977 |

5045 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

6/1 |

502 |

15 |

125 |

125 |

1032 |

6289 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

563 |

15 |

125 |

125 |

1093 |

7933 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

609 |

15 |

125 |

125 |

1139 |

6536 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

642 |

15 |

125 |

125 |

1172 |

10735 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

684 |

15 |

125 |

125 |

1214 |

8246 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

720 |

15 |

125 |

125 |

1250 |

13395 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

30/7 |

741 |

15 |

125 |

125 |

1271 |

16435 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

743 |

15 |

125 |

125 |

1273 |

9443 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

24/7 |

772 |

15 |

125 |

125 |

1302 |

13870 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

783 |

15 |

125 |

125 |

1313 |

15485 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

24/7 |

846 |

20 |

125 |

125 |

1386 |

16340 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

858 |

20 |

125 |

125 |

1398 |

18525 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

30/7 |

883 |

20 |

125 |

125 |

1423 |

22610 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

18/1 |

879 |

20 |

125 |

125 |

1419 |

13015 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

24/7 |

914 |

20 |

125 |

125 |

1454 |

18810 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

26/7 |

927 |

20 |

125 |

125 |

1467 |

21470 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 25kV AAAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

48.69 |

4 |

7 |

250 |

15 |

125 |

125 |

780 |

1584 |

225 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

77.47 |

2 |

7 |

316 |

15 |

125 |

125 |

846 |

2520 |

275 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

123.3 |

1/0 |

7 |

398 |

15 |

125 |

125 |

928 |

4014 |

348 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

155.4 |

2/0 |

7 |

447 |

15 |

125 |

125 |

977 |

4851 |

396 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

195.7 |

3/0 |

7 |

502 |

15 |

125 |

125 |

1032 |

6111 |

454 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

246.9 |

4/0 |

7 |

563 |

15 |

125 |

125 |

1093 |

7704 |

525 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

312.8 |

266.8 |

19 |

642 |

15 |

125 |

125 |

1172 |

9900 |

611 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

394.5 |

336.4 |

19 |

720 |

15 |

125 |

125 |

1251 |

11970 |

716 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

465.4 |

397.5 |

19 |

783 |

15 |

125 |

125 |

1313 |

14040 |

805 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

559.5 |

477 |

19 |

858 |

20 |

125 |

125 |

1398 |

16920 |

932 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

652.4 |

556.5 |

19 |

927 |

20 |

125 |

125 |

1467 |

19710 |

1044 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

740.8 |

636 |

37 |

990 |

20 |

125 |

125 |

1530 |

21960 |

1148 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

927.2 |

795 |

37 |

1108 |

20 |

125 |

125 |

1648 |

27450 |

1389 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 25kV AAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

7 |

336 |

15 |

125 |

125 |

866 |

1791 |

309 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

7 |

376 |

15 |

125 |

125 |

906 |

2259 |

350 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

7 |

423 |

15 |

125 |

125 |

953 |

2736 |

400 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

7 |

475 |

15 |

125 |

125 |

1005 |

3447 |

460 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

537 |

15 |

125 |

125 |

1067 |

4473 |

531 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

19 |

603 |

15 |

125 |

125 |

1133 |

5535 |

621 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

19 |

659 |

15 |

125 |

125 |

1189 |

6399 |

698 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

19 |

722 |

20 |

125 |

125 |

1262 |

7524 |

806 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

37 |

780 |

20 |

125 |

125 |

1320 |

8946 |

899 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

37 |

835 |

20 |

125 |

125 |

1375 |

10260 |

995 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

37 |

932 |

20 |

125 |

125 |

1472 |

12510 |

1181 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 35kV ACSR Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

6/1 |

398 |

15 |

175 |

125 |

1028 |

4161 |

448 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

6/1 |

447 |

15 |

175 |

125 |

1077 |

5045 |

509 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

6/1 |

563 |

15 |

175 |

125 |

1193 |

7933 |

673 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

18/1 |

609 |

15 |

175 |

125 |

1239 |

6536 |

684 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

26/7 |

642 |

15 |

175 |

125 |

1272 |

10735 |

770 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

18/1 |

684 |

15 |

175 |

125 |

1314 |

8246 |

794 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

26/7 |

720 |

15 |

175 |

125 |

1350 |

13395 |

901 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

30/7 |

741 |

15 |

175 |

125 |

1371 |

16435 |

1170 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

18/1 |

743 |

15 |

175 |

125 |

1373 |

9443 |

889 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

24/7 |

772 |

15 |

175 |

125 |

1402 |

13870 |

949 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

26/7 |

783 |

15 |

175 |

125 |

1413 |

15485 |

1013 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

24/7 |

846 |

20 |

175 |

125 |

1486 |

16340 |

1091 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

26/7 |

858 |

20 |

175 |

125 |

1498 |

18525 |

1168 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

30/7 |

883 |

20 |

175 |

125 |

1523 |

22610 |

1552 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

18/1 |

879 |

20 |

175 |

125 |

1519 |

13015 |

1138 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

24/7 |

914 |

20 |

175 |

125 |

1554 |

18810 |

1220 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

26/7 |

927 |

20 |

175 |

125 |

1567 |

21470 |

1309 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

18/1 |

940 |

20 |

175 |

125 |

1580 |

14915 |

1637 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

26/7 |

990 |

20 |

175 |

125 |

1630 |

23940 |

1826 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

26/7 |

1107 |

20 |

175 |

125 |

1747 |

29925 |

2146 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

45/7 |

1063 |

20 |

175 |

125 |

1703 |

20995 |

1892 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 35kV AAAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

48.69 |

4 |

7 |

250 |

15 |

175 |

125 |

880 |

1584 |

278 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

77.47 |

2 |

7 |

316 |

15 |

175 |

125 |

946 |

2520 |

333 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

123.3 |

1/0 |

7 |

398 |

15 |

175 |

125 |

1028 |

4014 |

411 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

155.4 |

2/0 |

7 |

447 |

15 |

175 |

125 |

1077 |

4851 |

462 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

195.7 |

3/0 |

7 |

502 |

15 |

175 |

125 |

1132 |

6111 |

523 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

246.9 |

4/0 |

7 |

563 |

15 |

175 |

125 |

1193 |

7704 |

598 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

312.8 |

266.8 |

19 |

642 |

15 |

175 |

125 |

1272 |

9900 |

689 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

394.5 |

336.4 |

19 |

720 |

15 |

175 |

125 |

1351 |

11970 |

799 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

465.4 |

397.5 |

19 |

783 |

15 |

175 |

125 |

1412 |

14040 |

892 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

559.5 |

477 |

19 |

858 |

20 |

175 |

125 |

1498 |

16920 |

1024 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

652.4 |

556.5 |

19 |

927 |

20 |

175 |

125 |

1567 |

19710 |

1141 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3-Layer 35kV AAC Tree Wire |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1/0 |

7 |

336 |

15 |

175 |

125 |

966 |

1791 |

368 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2/0 |

7 |

376 |

15 |

175 |

125 |

1006 |

2259 |

411 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3/0 |

7 |

423 |

15 |

175 |

125 |

1053 |

2736 |

464 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4/0 |

7 |

475 |

15 |

175 |

125 |

1105 |

3447 |

527 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

266.8 |

19 |

537 |

15 |

175 |

125 |

1167 |

4473 |

603 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

336.4 |

19 |

603 |

15 |

175 |

125 |

1233 |

5535 |

696 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

397.5 |

19 |

659 |

15 |

175 |

125 |

1289 |

6399 |

777 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

477 |

19 |

722 |

20 |

175 |

125 |

1362 |

7524 |

889 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

556.5 |

37 |

780 |

20 |

175 |

125 |

1420 |

8946 |

987 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

636 |

37 |

835 |

20 |

175 |

125 |

1475 |

10260 |

1085 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

795 |

37 |

932 |

20 |

175 |

125 |

1572 |

12510 |

1278 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

America Standard Covered Line Wire ANSI ICEA S-70-547

|

Code Name |

Size |

No. of wires |

Insulation Thickness (mm) |

Overall Diameter (mm) |

Rated Strength (kg) |

Nominal Weight (kg/km) |

Allowable Ampacity + A |

|||

|

AWG or kcmil |

Aluminum |

LDPE |

HDPE |

XLPE |

||||||

|

AAC |

||||||||||

|

Plum |

6 |

7 |

0.762 |

6.198 |

255 |

36.61 |

50.66 |

51.27 |

51.27 |

100 |

|

Apricot |

4 |

7 |

0.762 |

7.239 |

400 |

58.19 |

75.57 |

76.33 |

76.33 |

135 |

|

Peach |

2 |

7 |

1.143 |

9.703 |

612 |

92.56 |

126.09 |

127.55 |

127.55 |

180 |

|

Nectarine |

1 |

7 |

1.143 |

11.481 |

789 |

116.67 |

167.31 |

169.52 |

169.52 |

210 |

|

Quince |

1/0 |

7 |

1.524 |

12.395 |

903 |

147.48 |

203.7 |

206.14 |

206.14 |

240 |

|

Haw |

1/0 |

19 |

1.524 |

12.522 |

980 |

147.48 |

204.49 |

206.96 |

206.96 |

240 |

|

Orange |

2/0 |

7 |

1.524 |

14.834 |

1139 |

186.02 |

257.9 |

261.02 |

261.02 |

280 |

|

Ironwood |

2/0 |

19 |

1.524 |

13.691 |

1211 |

186.02 |

250.41 |

253.21 |

253.21 |

280 |

|

Fig |

3/0 |

7 |

1.524 |

16.307 |

1377 |

233.64 |

315.53 |

319.08 |

319.08 |

320 |

|

Lemon |

3/0 |

19 |

1.524 |

14.986 |

1501 |

233.64 |

306.53 |

309.7 |

309.7 |

320 |

|

Olive |

4/0 |

7 |

1.524 |

16.307 |

1728 |

296.14 |

378.04 |

381.58 |

381.58 |

370 |

|

Pomegranate |

4/0 |

19 |

1.524 |

16.459 |

1823 |

296.14 |

379.09 |

382.69 |

382.69 |

370 |

|

Sassalras |

250 |

19 |

1.524 |

17.628 |

2043 |

348.68 |

439.88 |

443.84 |

443.84 |

420 |

|

Mulberry |

266.8 |

19 |

1.524 |

17.653 |

2182 |

372.19 |

463.59 |

467.55 |

467.55 |

430 |

|

Basswood |

300 |

19 |

1.524 |

18.999 |

2404 |

419.66 |

520.91 |

525.3 |

525.3 |

478 |

|

Anona |

336.4 |

19 |

1.524 |

19.964 |

2697 |

469.51 |

578.04 |

582.75 |

582.75 |

495 |

|

Chinquapin |

350 |

19 |

1.524 |

20.269 |

2790 |

488.12 |

598.98 |

603.79 |

603.79 |

525 |

|

Molles |

397.5 |

19 |

2.032 |

22.454 |

3123 |

555.08 |

707.29 |

713.88 |

713.88 |

550 |

|

Sumac |

450 |

37 |

2.032 |

23.673 |

3719 |

628 |

791.79 |

798.89 |

798.89 |

600 |

|

Huckleberry |

477 |

37 |

2.032 |

24.257 |

3810 |

665.21 |

834.63 |

841.98 |

841.98 |

610 |

|

ACSR |

||||||||||

|

Walnut |

6 |

6-1 |

0.762 |

6.553 |

540 |

36.64 |

69.94 |

71.43 |

71.43 |

105 |

|

Butternut |

4 |

6-1 |

0.762 |

7.874 |

844 |

58.04 |

107.15 |

107.15 |

107.15 |

135 |

|

Hickory |

4 |

7-1 |

0.762 |

8.052 |

1070 |

58.04 |

120.54 |

122.03 |

122.03 |

135 |

|

Pignut |

2 |

6-1 |

1.143 |

10.312 |

1293 |

92.27 |

175.6 |

177.09 |

177.09 |

180 |

|

Beech |

2 |

7-1 |

1.143 |

10.643 |

1651 |

92.27 |

199.41 |

199.41 |

199.41 |

180 |

|

Chestnut |

1 |

6-1 |

1.143 |

11.303 |

1610 |

116.37 |

17.27 |

218.76 |

218.76 |

210 |

|

Almond |

1/0 |

6-1 |

1.524 |

13.157 |

1987 |

146.73 |

282.75 |

284.24 |

284.24 |

235 |

|

Pecan |

2/0 |

6-1 |

1.524 |

14.402 |

2404 |

184.98 |

348.23 |

349.72 |

349.72 |

290 |

|

Filbert |

3/0 |

6-1 |

1.524 |

15.799 |

3003 |

233.34 |

430.08 |

433.05 |

433.05 |

305 |

|

Buckeye |

4/0 |

6-1 |

1.524 |

17.348 |

3787 |

394.21 |

531.27 |

535.74 |

535.74 |

345 |

|

Hackberry |

266.8 |

1-18 |

1.524 |

18.517 |

3121 |

372.63 |

525.32 |

528.3 |

528.3 |

356 |

|

AAAC |

||||||||||

|

Maple |

6 |

7 |

0.762 |

6.553 |

503 |

42.41 |

59.53 |

61.01 |

61.01 |

78 |

|

Hornbeam |

4 |

7 |

0.762 |

7.874 |

798 |

67.56 |

89.29 |

90.78 |

90.78 |

145 |

|

Linden |

2 |

7 |

1.143 |

10.312 |

1270 |

107.44 |

147.33 |

147.33 |

147.33 |

190 |

|

Oilnut |

1/0 |

7 |

1.524 |

11.887 |

2023 |

170.99 |

238.11 |

247.03 |

247.03 |

250 |

|

Waterash |

2/0 |

7 |

1.524 |

14.402 |

2445 |

215.63 |

291.68 |

302.01 |

302.01 |

290 |

|

Shellbark |

3/0 |

7 |

1.524 |

15.799 |

3080 |

271.59 |

358.65 |

370.55 |

370.55 |

335 |

|

Planetree |

4/0 |

7 |

1.524 |

17.348 |

3883 |

342.57 |

443.47 |

456.86 |

456.86 |

385 |

British Standard BS6485 Covered Line Wire

|

Code Name |

Nominal |

Calculatec |

Wires |

Approx. Overall Dia. |

Nominal |

Max.D.C. Resistance at20P |

Alum. Weight |

PVC Insulated Overall Diameter |

PVC Insulated Total Weight |

Packing Length |

|

|

Area |

Area |

No. |

Dia. |

Load |

|||||||

|

|

mm' |

mm2 |

|

mm |

mm |

kN |

Q/km |

kg/km |

mm |

kg/km |

m±5% |

|

Midge |

22 |

23.33 |

7 |

2.06 |

6.2 |

3.99 |

1.227 |

64 |

8.4 |

106 |

3000 |

|

Aphis |

25 |

26.44 |

3 |

3.35 |

7.2 |

4.11 |

1.081 |

73 |

9.2 |

133 |

3000 |

|

Gnat |

25 |

26.8 |

7 |

2.21 |

6.6 |

4.59 |

1.066 |

73 |

8.8 |

116 |

3000 |

|

Weevil |

30 |

31.6 |

3 |

3.66 |

7.9 |

4.86 |

0.9082 |

86 |

10.1 |

158 |

3000 |

|

Mosouito |

35 |

37 |

7 |

2.59 |

7.8 |

6.03 |

0.7762 |

101 |

10.0 |

158 |

3000 |

|

Ladybird |

40 |

42.8 |

7 |

2.79 |

8.4 |

6.87 |

0.6689 |

117 |

10.6 |

177 |

3000 |

|

Ant |

50 |

52.83 |

7 |

3.1 |

9.3 |

8.28 |

0.5419 |

145 |

11.5 |

212 |

3000 |

|

Fly |

60 |

63.55 |

7 |

3.4 |

10.2 |

9.9 |

0.4505 |

174 |

12.4 |

249 |

2500 |

|

Blueeottle |

70 |

73.55 |

7 |

3.66 |

11.0 |

11.34 |

0.3881 |

202 |

13.2 |

285 |

2500 |

|

Earwing |

75 |

78.5 |

7 |

3.78 |

11.4 |

11.94 |

0.3644 |

215 |

13.6 |

302 |

2000 |

|

Grasshopper |

80 |

84.1 |

7 |

3.91 |

11.7 |

12.78 |

0.3406 |

230 |

13.9 |

319 |

2000 |

|

Clegg |

90 |

95.6 |

7 |

4.17 |

12.5 |

14.53 |

0.2994 |

262 |

14.7 |

359 |

2000 |

|

Wasp |

100 |

108 |

7 |

4.39 |

13.21 |

16.0 |

0.2702 |

290 |

15.4 |

393 |

3000 |

|

Beetle |

100 |

106.6 |

19 |

2.67 |

13.4 |

17.42 |

0.2704 |

293 |

15.6 |

387 |

3000 |

|

Bee |

125 |

132 |

7 |

4.9 |

14.7 |

19.94 |

0.2169 |

361 |

16.5 |

482 |

2500 |

|

Cricket |

150 |

157.9 |

7 |

5.36 |

16.1 |

23.85 |

0.1813 |

432 |

18.3 |

587 |

2000 |

|

Hornet |

150 |

157.6 |

19 |

3.25 |

16.3 |

27.7 |

0.1825 |

434 |

18.5 |

638 |

3000 |

|

Caterpillar |

175 |

186 |

19 |

3.53 |

17.7 |

28.63 |

0.1547 |

512 |

19.9 |

646 |

2500 |

|

Chafer |

200 |

213.2 |

19 |

3.78 |

18.9 |

32.4 |

0.1349 |

587 |

21.1 |

733 |

2000 |

|

Spider |

225 |

236.9 |

19 |

3.99 |

20.0 |

36.01 |

0.1211 |

652 |

22.2 |

809 |

2000 |

|

Cockroach |

250 |

265.7 |

19 |

4.22 |

21.1 |

40.4 |

0.1083 |

731 |

23.3 |

900 |

3000 |

|

Butterfly |

300 |

322.7 |

19 |

4.65 |

23.3 |

48.7 |

0.08916 |

888 |

25.5 |

1082 |

3000 |

|

Moth |

350 |

373.2 |

19 |