PE AND XLPE INSULATED AERIAL BUNDLE CABLES

PUBLICATIONS REFERRED TO

| IEC 60502-1 | Power Cables With Extruded Insulation And Their Accessories For Rated Voltages From l kV ( Um = l.2 kV) Up To 30 kV ( Um = 36 kV ). |

| TNB | Specification for Low Voltage Aerial Bundle Cable |

| AS/NZS 3560.1 | Electric cables – Cross-linked polyethylene insulated – Aerial bundled – For working voltage up to and including 0.6/l(l.2) kV |

| BS 7870-5 | Polymeric insulated aerial bundled conductors (ABC ) of rated voltage 0.6/l kV for overhead distribution |

| DES/LV/ABC | Specification for Low Voltage Aerial Bundle Conductor (Aluminium ) |

| AS/NZS 3599.1 | Electric cables – Aerial bundled – Polymeric insulated – Voltages 6.35/ll (l2) kV and l2.7/22 (24) kV |

| AS/NZS 3599.2 | Electric cables – Aerial bundled – Polymeric insulated – Voltages 6.35/ll (l2) kV and l2.7/22 (24) kV |

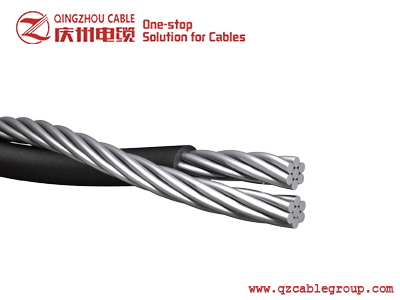

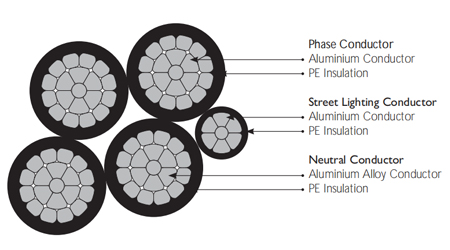

AL/PE INSULATED AERIAL BUNDLED CABLES IEC 60502&TNB Specification 0.6/1 (1.2) kV

DESCRIPTION

The aerial bundled cables designed for overhead distribution lines have an insulated neutral messenger made of AAAC, which the insulated aluminium phase conductors are helically wound over it. Cables are rated at 0.6/l(l.2) kV and conform to IEC 60502 & TNB Specification.

CONSTRUCTION

- Conductor :

Phase – The phase conductors shall be of H68 Condition aluminium conductor and compacted circular stranded. Neutral or messenger – The neutral or messenger conductor shall be of aluminium alloy conductor and compacted circular stranded. Street Lighting – The street lighting conductors shall be of H68 Condition aluminium conductor and compacted circular stranded.

- Insulation :

The phase, neutral and street lighting conductors shall be extruded with Polyethylene (PE) as insulation.

- Assembly:

The cable consists of insulated phase and street lighting aluminium conductors, shall be held firmly onto the insulated neutral messenger aluminium alloy conductor in a right hand (Z) lay.

IEC 60502 & TNB Specifcation(0.6/1 (1.2) kV)Cables without street lighting

| Phase conductor | |||||||||||

| Nominal cross-sectional area | mm2 | 16 * | 16 * | 25 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 6 | 6 | 12 | 15 | 15 | 30 | 30 | |

| Nominal insulation thickness | mm | 1 | 1 | 1.2 | 1.2 | l.4 | l.4 | 1.6 | 1.6 | l.8 | 2 |

| Diameter of insulated core | mm | 6.8 | 6.8 | 8.5 | 9.5 | 11.2 | 13 | 15.1 | 16.6 | l8.4 | 20.6 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.91 | 1.2 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at still wind, ambient temperature =30°C, conductor temperature = 75°C | A | 61 | 61 | 84 | l04 | 129 | 167 | 209 | 246 | 283 | 332 |

| Maximum voltage drop | mV/A/m | 4.67 | 4.05 | 2.54 | l.84 | 1.36 | 0.95 | 0.69 | 0.55 | 0.46 | 0.37 |

| Messenger conductor | |||||||||||

| Nominal cross-sectional area | mm2 | 25 | 25 | 25 | 25 | 35 | 50 | 70 | 70 | 95 | 120 |

| Minimum number of wires | 6 | 6 | 6 | 6 | 6 | 6 | 12 | 12 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | l.4 | l.4 | l.4 | 1.6 | 1.6 |

| Diameter of insulated core | mm | 8.5 | 8.5 | 8.5 | 8.5 | 9.5 | 11.2 | 13.1 | 13.1 | 15.1 | 16.6 |

| Max. dc resistance at 20°C | ohm/km | 1.312 | 1.312 | 1.312 | 1.312 | 0.943 | 0.693 | 0.469 | 0.469 | 0.349 | 0.273 |

| Calculated breaking load | kN | 6.4 | 6.4 | 6.4 | 6.4 | 8.9 | 12.1 | l8.0 | l8.0 | 24.2 | 30.8 |

| Completed cable | |||||||||||

| Approx. overall diameter | mm | 15.3 | 19 | 23.2 | 25.6 | 30 | 34.9 | 40.6 | 44.l | 49.2 | 54.9 |

| Approx. weight of cable | kg/km | 160 | 290 | 400 | 500 | 680 | 920 | 1270 | 1510 | l,870 | 2340 |

| Packing length | m/drum | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 500 | 500 | 500 | 500 |

IEC 60502 & TNB Specifcation(0.6/1 (1.2) kV)Cables with street lighting

| Phase conductor | |||||||||

| Nominal cross-sectional area | mm2 | 25 | 35 | 50 | 70 | 95 * | 120 | 150 | 185* |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | 15 | 30 | 30 | |

| Nominal insulation thickness | mm | 1.2 | 1.2 | l.4 | l.4 | 1.6 | 1.6 | l.8 | 2 |

| Diameter of insulated core | mm | 8.5 | 9.5 | 11.2 | 13 | 15.1 | 16.6 | l8.4 | 20.6 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at still wind, ambient temperature = 30°C, conductor temperature = 75°C | A | 84 | l04 | 129 | 167 | 209 | 246 | 283 | 332 |

| Maximum voltage drop | mV/A/m | 2.54 | l.84 | 1.36 | 0.95 | 0.69 | 0.55 | 0.46 | 0.37 |

| Messenger conductor | |||||||||

| Nominal cross-sectional area | mm2 | 25 | 25 | 35 | 50 | 70 | 70 | 95 | 120 |

| Minimum number of wires | 6 | 6 | 6 | 6 | 12 | 12 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.2 | 1.2 | 1.2 | l.4 | l.4 | l.4 | 1.6 | 1.6 |

| Diameter of insulated core | mm | 8.5 | 8.5 | 9.5 | 11.2 | 13.1 | 13.1 | 15.1 | 16.6 |

| Max. dc resistance at 20°C | ohm/km | 1.312 | 1.312 | 0.943 | 0.693 | 0.469 | 0.469 | 0.349 | 0.273 |

| Calculated breaking load | kN | 6.4 | 6.4 | 8.9 | 12.1 | l8.0 | l8.0 | 24.2 | 30.8 |

| Street lighting conductor | |||||||||

| Nominal cross-sectional area | mm2 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Minimum number of wires | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Nominal insulation thickness | mm | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Diameter of insulated core | mm | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.91 | 1.91 | 1.91 | 1.91 | 1.91 | 1.91 | 1.91 |

| Completed cable | |||||||||

| Approx. overall diameter | mm | 23.2 | 25.6 | 30 | 34.9 | 40.6 | 44.l | 49.2 | 54.9 |

| Approx. weight of cable | kg/km | 470 | 560 | 740 | 980 | 1330 | l,580 | l,940 | 2,4l0 |

| Packing length | m/drum | 1000 | 1000 | 1000 | 1000 | 500 | 500 | 500 | 500 |

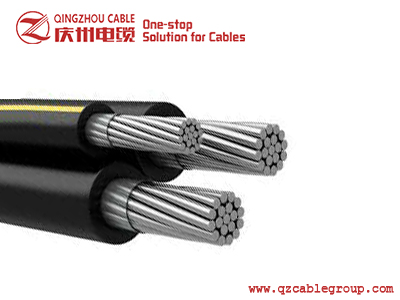

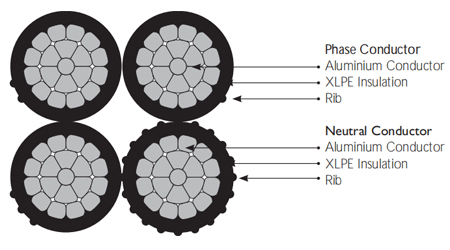

AL/XLPE INSULATED AERIAL BUNDLED CABLES AS/NZS 3560.1 0.6/1 (1.2) kV

DESCRIPTION

The aerial bundled cables designed for overhead distribution lines have all conductors made of aluminium 1350 and are insulated with XLPE. Phase and neutral cores are laid up in a bundle with a left hand lay. Cables are rated at 0.6/l(l.2) kV and conform to AS/ NZS 3560.l. The main advantage of aerial bundled cables include :

- Ease of erection and stringing

- Practically no tree – trimming required

- Less maintenance

CONSTRUCTION

- Conductor (For both phase and neutral):

The conductors shall be of aluminium 1350 wires and are compacted circular stranded.

- Insulation :

The conductors shall be extruded with Cross-linked Polyethylene (XLPE) material as insulation. Each phase core is marked with numerals and letters l ONE, 2TWO or 3 THREE and with one rib, two ribs or three ribs to denote the phases.The neutral core carries equally spaced ribs right round the circumference.

- Assembly:

The cores shall be laid up with a left hand (S) lay.

AL/XLPE INSULATED AERIAL BUNDLED CABLES AS/NZS 3560.1 0.6/1 (1.2) kV

| Phase conductor | |||||||||

| Nominal cross-sectional area | mm2 | 16 | 25 | 35 | 50 | 95 | 25 | 35 | 50 |

| Number of cores | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | |

| Minimum number of wires | 6 | 6 | 6 | 6 | 15 | 6 | 6 | 6 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.7 | 1.3 | 1.3 | 1.5 |

| Diameter of insulated core | mm | 7.5 | 8.8 | 9.8 | ll.4 | 15.3 | 8.8 | 9.8 | ll.4 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.2 | 0.868 | 0.641 | 0.32 | 1.2 | 0.868 | 0.64l |

| Current rating for typical Australian installation conditions Conductor temperature = 80°C | A | 78 | 105 | 125 | 150 | 230 | 97 | 120 | l40 |

| Neutral conductor | |||||||||

| Nominal cross-sectional area | mm2 | 16 | 25 | 35 | 50 | 95 | 25 | 35 | 50 |

| Minimum number of wires | 6 | 6 | 6 | 6 | 15 | 6 | 6 | 6 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.7 | 1.3 | 1.3 | 1.5 |

| Diameter of insulated core | mm | 7.5 | 8.8 | 9.8 | ll.4 | 15.3 | 8.8 | 9.8 | ll.4 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.2 | 0.868 | 0.64l | 0.32 | 1.2 | 0.868 | 0.64l |

| Completed cable | |||||||||

| Minimum breaking load | kN | 4.4 | 7 | 9.8 | l4.0 | 26.6 | 10.5 | l4.7 | 21 |

| Approx. overall diameter | mm | 15 | 17.6 | 19.6 | 22.8 | 30.6 | 19 | 21.1 | 24.6 |

| Approx. weight of cable | kg/km | l40 | 210 | 270 | 370 | 680 | 310 | 4l0 | 550 |

| Packing length | m/drum | 1000 | 1000 | 1000 | 1000 | 500 | 1000 | 1000 | 1000 |

| Phase conductor | |||||||||

| Nominal cross-sectional area | mm2 | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 6 | 12 | 15 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.7 | 1.7 |

| Diameter of insulated core | mm | 7.5 | 8.8 | 9.8 | ll.4 | 13.2 | 15.3 | l6.8 | l8.2 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.2 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 |

| Current rating for typical Australian installation conditions Conductor temperature = 80°C | A | 74 | 97 | 120 | l40 | 175 | 215 | 250 | 280 |

| Neutral conductor | |||||||||

| Nominal cross-sectional area | mm2 | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 |

| Minimum number of wires | 6 | 6 | 6 | 6 | 12 | 15 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.7 | 1.7 |

| Diameter of insulated core | mm | 7.5 | 8.8 | 9.8 | ll.4 | 13.2 | 15.3 | l6.8 | l8.2 |

| Max. dc resistance at 20°C | ohm/km | 1.91 | 1.2 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 |

| Completed cable | |||||||||

| Minimum breaking load | kN | 8.8 | l4.0 | 19.6 | 28 | 39.2 | 53.2 | 67.2 | 84 |

| Approx. overall diameter | mm | l8.l | 21.2 | 23.7 | 27.5 | 31.9 | 36.9 | 40.6 | 43.9 |

| Approx. weight of cable | kg/km | 290 | 4l0 | 550 | 740 | 1000 | 1370 | 1690 | 2020 |

| Packing length | m/drum | 1000 | 1000 | 1000 | 1000 | 1000 | 500 | 500 | 500 |

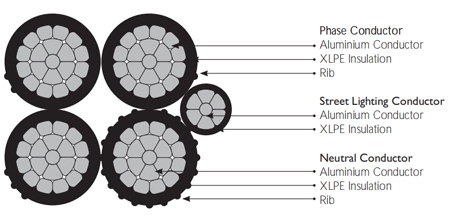

AL/XLPE INSULATED AERIAL BUNDLED CABLES BS 7870-5 0.6/1 (1.2) kV

DESCRIPTION

The aerial bundled cables designed for overhead distribution lines have all conductors made of aluminium 1350 and are insulated with XLPE . Phase and neutral cores are laid up in a bundle with a left hand lay. Cables are rated at 0.6/l(l.2) kV and conform to BS 7870-5. The main advantage of aerial bundled cables include :

- Ease of erection and stringing

- Practically no tree – trimming required

- Less maintenance

CONSTRUCTION

- Conductor (For either phase, neutral or street lighting):

The conductors shall be of aluminium 1350 wires and are compacted circular stranded.

- Insulation :

The conductors shall be extruded with Cross-linked Polyethylene (XLPE ) material as insulation. Each phase core is marked with numerals and letters l ONE, 2TWO or 3 THREE and with one rib, two ribs or three ribs to denote the phases.The neutral core carries equally spaced ribs right round the circumference.

- Assembly:

The cores shall be laid up with a left hand (S) lay.

BS 7870-5 0.6/1 (1.2) kV Cables without street lighting

| Phase conductor | ||||||||||||

| Nominal cross-sectional area | mm2 | 25 | 35 | 50 | 70 | 95 | 25 | 35 | 50 | 70 | 95 | 120 |

| Number of cores | 1 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | 6 | 6 | 6 | 12 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.7 |

| Diameter of insulated core | mm | 8.8 | 9.8 | 11.5 | 13.2 | 15.3 | 8.8 | 9.8 | 11.5 | 13.2 | 15.3 | 16.8 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 0.868 | 0.641 | 0.443 | 0.32 | 1.2 | 0.868 | 0.641 | 0.443 | 0.32 | 0.253 |

| Current rating at still wind ambient temperature = 30°C Conductor temperature = 75°C | A | 84 | 104 | 129 | 167 | 209 | 84 | 104 | 129 | 167 | 209 | 283 |

| Neutral conductor | ||||||||||||

| Nominal cross-sectional area | mm2 | 25 | 35 | 50 | 70 | 95 | 25 | 35 | 50 | 70 | 95 | 120 |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | 6 | 6 | 6 | 12 | 15 | 15 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.3 | 1.3 | 1.5 | 1.5 | 1.7 | 1.7 |

| Diameter of insulated core | mm | 8.8 | 9.8 | 11.5 | 13.2 | 15.3 | 8.8 | 9.8 | 11.5 | 13.2 | 15.3 | 16.8 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 0.868 | 0.641 | 0.443 | 0.32 | 1.2 | 0.868 | 0.641 | 0.443 | 0.32 | 0.253 |

| Completed cable | ||||||||||||

| Minimum breaking load | kN | 8.2 | 11.2 | 15.2 | 22 | 30.6 | l6.4 | 22.4 | 30.4 | 44 | 61.2 | 77.6 |

| Approx. overall diameter | mm | 17.6 | 19.6 | 23 | 26.4 | 30.6 | 21.2 | 23.7 | 27.8 | 31.9 | 36.9 | 40.6 |

| Approx. weight of cable | kg/km | 210 | 270 | 360 | 500 | 680 | 4l0 | 550 | 730 | 1000 | 1370 | 1690 |

| Packing length | m/drum | 1000 | 1000 | 1000 | 1000 | 500 | 1000 | 1000 | 1000 | 1000 | 500 | 500 |

BS 7870-5 0.6/1 (1.2) kV Cables without street lighting Cables with street lighting

| Phase conductor | ||||

| Nominal cross-sectional area | mm2 | 50 | 70 | 95 |

| Number of cores | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 12 | 15 | |

| Nominal insulation thickness | mm | 1.5 | 1.5 | 1.7 |

| Diameter of insulated core | mm | 11.5 | 13.2 | 15.3 |

| Max. dc resistance at 20°C | ohm/km | 0.64l | 0.443 | 0.32 |

| Current rating at still wind, ambient temperature = 30°C conductor temperature = 75°C | A | 129 | 167 | 209 |

| Neutral conductor | ||||

| Nominal cross-sectional area | mm2 | 50 | 70 | 95 |

| Minimum number of wires | 6 | 12 | 15 | |

| Nominal insulation thickness | mm | 1.5 | 1.5 | 1.7 |

| Diameter of insulated core | mm | 11.5 | 11.5 | 15.3 |

| Max. dc resistance at 20°C | ohm/km | 0.64l | 0.443 | 0.32 |

| Street lighting conductor | ||||

| Nominal cross-sectional area | mm2 | 25 | 25 | 25 |

| Minimum number of wires | 6 | 6 | 6 | |

| Nominal insulation thickness | mm | 1.3 | 1.3 | 1.3 |

| Diameter of insulated core | mm | 8.8 | 8.8 | 8.8 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 1.2 | 1.2 |

| Completed cable | ||||

| Minimum breaking load | kN | 34.5 | 48.l | 65.3 |

| Approx. overall diameter | mm | 29.8 | 33.6 | 38.2 |

| Approx. weight of cable | kg/km | 830 | 1100 | l470 |

| Packing length | m/drum | 1000 | 1000 | 500 |

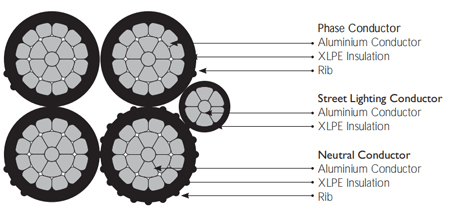

AL/XLPE INSULATED AERIAL BUNDLED CABLES IEC 60502 & DES/LV/ABC 0.6/1 (1.2) kV

DESCRIPTION

The aerial bundled cables designed for overhead distribution lines have all conductors made of aluminium 1350 and are insulated with XLPE. Phase and neutral cores are laid up in a bundle with a left hand lay. Cables are rated at 0.6/l(l.2) kV and conform to IEC 60502 & DES/LV/ABC. The main advantage of aerial bundled cables include :

- Ease of erection and stringing

- Practically no tree – trimming required

- Less maintenance

CONSTRUCTION

- Conductor (For either phase, neutral or street lighting):

The conductors shall be of H68 condition aluminium conductor and compacted circular stranded.

- Insulation :

The conductors shall be extruded with Cross-linked Polyethylene (XLPE ) material as insulation. Each phase core is marked with one rib, two ribs or three ribs to denote the phases .The neutral core carries equally spaced ribs right round the circumference.The street lighting core is marked with the letter" S/L".

- Assembly:

The cores shall be laid up with a left hand (S) lay.

IEC 60502 & DES/LV/ABC 0.6/1 (1.2) kV Cables without street lighting

| Phase conductor | |||

| Nominal cross-sectional area | mm2 | 25 | 35 |

| Number of cores | 3 | 3 | |

| Minimum number of wires | 6 | 6 | |

| Nominal insulation thickness | mm | l.4 | l.4 |

| Diameter of insulated core | mm | 8.9 | 9.9 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 0.868 |

| Minimum breaking load | kN | 3.5 | 4.9 |

| Current rating at still wind, ambient temperature = 30°C, conductor temperature = 75°C | A | 84 | 104 |

| Neutral Conductor | |||

| Nominal cross-sectional area | mm2 | 25 | 35 |

| Minimum number of wires | 6 | 6 | |

| Nominal insulation thickness | mm | l.4 | l.4 |

| Diameter of insulated core | mm | 8.9 | 9.9 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 0.868 |

| Minimum breaking load | kN | 3.5 | 4.9 |

| Completed cable | |||

| Approx. overall diameter | mm | 21.5 | 23.9 |

| Approx. weight of cable | kg/km | 420 | 550 |

| Packing length | m/drum | 1000 | 1000 |

IEC 60502 & DES/LV/ABC 0.6/1 (1.2) kV Cables with street lighting

| Phase conductor | |||

| Nominal cross-sectional area | mm2 | 120 | l85 |

| Number of cores | 3 | 3 | |

| Minimum number of wires | 15 | 30 | |

| Nominal insulation thickness | mm | 1.7 | 2.2 |

| Diameter of insulated core | mm | 17 | 21 |

| Max. dc resistance at 20°C | ohm/km | 0.253 | 0.l64 |

| Minimum breaking load | kN | l6.8 | 25.9 |

| Current rating at still wind, ambient temperature = 30°C, conductor temperature = 75°C | A | 246 | 332 |

| Neutral conductor | |||

| Nominal cross-sectional area | mm2 | 120 | l85 |

| Minimum number of wires | 15 | 30 | |

| Nominal insulation thickness | mm | 1.7 | 2.2 |

| Diameter of insulated core | mm | 17 | 21 |

| Max. dc resistance at 20°C | ohm/km | 0.253 | 0.l64 |

| Minimum breaking load | kN | l6.8 | 25.9 |

| Street lighting conductor | |||

| Nominal cross-sectional area | mm2 | 25 | 25 |

| Minimum number of wires | 6 | 6 | |

| Nominal insulation thickness | mm | l.4 | l.4 |

| Diameter of insulated core | mm | 8.9 | 8.9 |

| Max. dc resistance at 20°C | ohm/km | 1.2 | 1.2 |

| Completed cable | |||

| Approx. overall diameter | mm | 43.8 | 50.7 |

| Approx. weight of cable | kg/km | l,800 | 2700 |

| Packing length | m/drum | 500 | 500 |

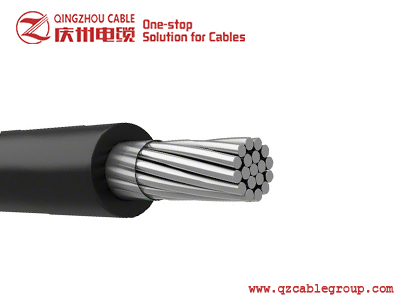

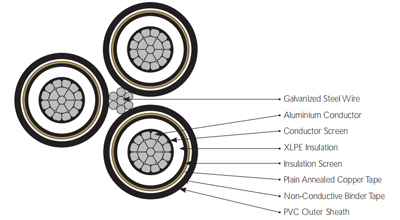

AL/XLPE INSULATED, PVC OUTER SHEATHED AERIAL BUNDLED CABLES AL/XLPE/SCT/PVC CABLES , MEDIUM VOLTAGE IEC 60502 & TNB Specifcation

DESCRIPTION

Circular compacted stranded aluminium conductor; XLPE insulated, copper tape screened and PVC outer sheathed cable.The three XLPE insulated and copper tape screened single core cables are bundled around the galvanized steel wires in a right hand lay.

CONSTRUCTION

-

Conductor Phase conductors are circular compacted stranded H68 aluminium to BS2627.

-

Conductor screen Extruded layer of semi-conductive compound.

-

Insulation XLPE (cross-linked polyethylene) rated at 90°C.

-

Insulation screen: Non-metallic part: Extruded layer of semi-conductive compound. Metallic part: Copper tape screen ( SCT ).

-

Colour for core identification Red, yellow and blue tapes shall be applied between non metallic andmetallic part of insulation Separator Polypropylene laminated tape.

-

Outer sheath PVC type ST2 to IEC 60502 colour black.The outer sheath shall be embossed with figures l, 2, 3corresponding to red, yellow, blue phase.

-

Support wire The support wire shall comprise a stranded galvanized steel wires

-

Assembly The three XLPE insulated and copper wire screened single core cables are bundled around the galvanized steel steelwires in a right hand (Z) lay.

AERIAL BUNDLED CABLES AL/XLPE/SCT/PVC CABLES IEC 60502 & TNB Specifcation 6.35/11 (12) kV

| Phase conductor | ||||||||

| Nominal cross-sectional area | mm2 | 50 | 70 | 95 | 120 | 150 | l85 | 240 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 12 | 15 | 15 | 15 | 30 | 30 | |

| Nominal diameter of conductor | mm | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 | l8.4 |

| Nominal thickness of XLPE insulation | mm | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 |

| Metallic screening approx. thickness of copper tape | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Nominal thickness of outer sheath | mm | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 |

| Nominal diameter over sheathing | mm | 23 | 24.6 | 26.3 | 27.8 | 29.2 | 30.9 | 33.3 |

| Max. dc resistance at 20°C | ohm/km | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 | 0.125 |

| Earth fault current carrying capacity of metallic screen at | ||||||||

| -1 second ( 1 Core ) | kA | 1.57 | 1.72 | 1.88 | 2.01 | 2.l4 | 2.3 | 2.52 |

| -3 seconds ( 1 Core ) | kA | 0.9 | 0.99 | l.08 | 1.16 | 1.23 | 1.33 | l.45 |

| Messenger – Galvanized steel wire | ||||||||

| Nominal cross-sectional area | mm2 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Stranding | No./mm | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 |

| Direction of the outermost layer Righthand (Z) | ||||||||

| Overall diameter | mm | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 |

| Minimum breaking load | kg | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 |

| Completed cable | ||||||||

| Approx. overall diameter | mm | 55 | 59 | 62 | 65 | 67 | 71 | 75 |

| Approx. weight of cable | kg/km | 2540 | 2890 | 3300 | 3660 | 4040 | 4540 | 5290 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

AERIAL BUNDLED CABLES AL/XLPE/SCT/PVC CABLES IEC 60502 & TNB Specifcation 12.7/22 (24) kV

| Phase conductor | ||||||||

| Nominal cross.sectional area | mm2 | 50 | 70 | 95 | 120 | 150 | l85 | 240 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 12 | 15 | 15 | 15 | 30 | 30 | |

| Nominal diameter of conductor | mm | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 | l8.4 |

| Nominal thickness of XLPE insulation | mm | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Metallic screening approx. thickness of copper tape | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Nominal thickness of outer sheath | mm | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 |

| Nominal diameter over sheathing | mm | 27.2 | 28.8 | 30.5 | 32 | 33.4 | 35.1 | 37.5 |

| Max. dc resistance at 20°C | ohm/km | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 | 0.125 |

| Earth fault current carrying capacity of metallic screen at | ||||||||

| -1 second ( 1 Core ) | kA | 1.96 | 2.11 | 2.26 | 2.4 | 2.53 | 2.68 | 2.9 |

| -3 seconds ( 1 Core ) | kA | 1.13 | 1.21 | 1.31 | l.38 | l.46 | 1.55 | 1.67 |

| Messenger – Galvanized steel wire | ||||||||

| Nominal cross-sectional area | mm2 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Stranding | No./mm | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 |

| Direction of the outermost layer Right-hand (Z) | ||||||||

| Overall diameter | mm | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 |

| Minimum breaking load | kg | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 |

| Completed cable | ||||||||

| Approx. overall diameter | mm | 64 | 67 | 70 | 73 | 75 | 78 | 83 |

| Approx. weight of cable | kg/km | 3150 | 3540 | 3980 | 4360 | 4770 | 5300 | 6100 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 500 | 250 | 250 |

AERIAL BUNDLED CABLES AL/XLPE/SCT/PVC CABLES IEC 60502 & TNB Specifcation 19/33 (36) kV

| Phase conductor | ||||||||

| Nominal cross-sectional area | mm2 | 50 | 70 | 95 | 120 | 150 | l85 | 240 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 12 | 15 | 15 | 15 | 30 | 30 | |

| Nominal diameter of conductor | mm | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 | l8.4 |

| Nominal thickness of XLPE insulation | mm | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Metallic screening approx. thickness of copper tape | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Nominal thickness of outer sheath | mm | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 |

| Nominal diameter over sheathing | mm | 32.2 | 33.8 | 35.5 | 37 | 38.4 | 40.l | 42.5 |

| Max. dc resistance at 20°C | ohm/km | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 | 0.125 |

| Earth fault current carrying capacity of metallic screen at | ||||||||

| -1 second ( 1 Core ) | kA | 2.4l | 2.56 | 2.72 | 2.86 | 2.99 | 3.l4 | 3.36 |

| -3 seconds ( 1 Core ) | kA | 1.39 | l.48 | 1.57 | 1.65 | 1.72 | l.8l | l.94 |

| Messenger – Galvanized steel wire | ||||||||

| Nominal cross.sectional area | mm2 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Stranding | No./mm | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 | 7/3.l5 |

| Direction of the outermost layer | Righthand (Z) | |||||||

| Overall diameter | mm | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 | 9.45 |

| Minimum breaking load | kg | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 | 6270 |

| Completed cable | ||||||||

| Approx. overall diameter | mm | 73 | 76 | 79 | 82 | 84 | 87 | 91 |

| Approx. weight of cable | kg/km | 3980 | 4400 | 4880 | 5300 | 5740 | 6310 | 7160 |

| Packing length | m/drum | 500 | 500 | 500 | 250 | 250 | 250 | 250 |

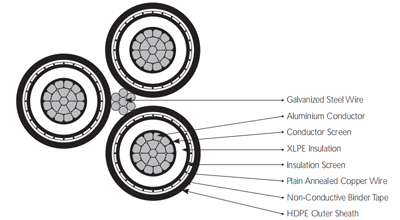

AL/XLPE INSULATED, PE OUTER SHEATHED AERIAL BUNDLED CABLES AL/XLPE/SCW/HDPE AERIAL CABLES , MEDIUM VOLTAGE 19/33 (36) kV AS/NZS 3599.1

DESCRIPTION

Circular compacted stranded aluminium conductor; XLPE insulated, copper wire screened and HDPE outer sheathed cable.The three XLPE insulated and copper wire screened single core cables are bundled around the galvanized steel wires in a right hand lay.

CONSTRUCTION

-

Conductor Phase conductors are circular compacted stranded H68 aluminium to BS2627.

-

Conductor screen Extruded layer of semi-conductive compound.

-

Insulation XLPE (cross-linked polyethylene) rated at 90°C.

-

Insulation screen: a Non-metallic part Extruded layer of semi-conductive compound. b Metallic part Copper wire screen ( SCW ).

-

Separator Non conductive swellable binder tape Note : A semi-conductive swellable tape may be applied in between the non-

-

metallic and metallic part.

-

Outer sheath High density polyethylene (HDPE) colour black.The outer sheath shall be printed with figures l ONE, 2 TWO, 3 THREE which corresponding to the three different phases.

-

Support wire The support wire shall comprise a stranded galvanized steel wires.

-

Assembly The three XLPE insulated and copper wire screened single core cables are bundled aroundthe galvanized steel wires in a right hand (Z) lay.

AL/XLPE/SCW/HDPE AERIAL BUNDLED CABLES AS/NZS 3599.1 (Light Duty Screen) 6.35/11 (12) kV

| Phase conductor | |||||||||

| Nominal cross-sectional area | mm2 | 35 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 7 | 8.l | 9.7 | l4.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 |

| Minimum thickness of insulation screen | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| No. and diameter of metallic screening approx. of copper wire | no./mm | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 |

| Nominal thickness of outer sheath | mm | l.8 | l.8 | l.8 | l.8 | l.8 | l.8 | l.8 | 1.9 |

| Nominal diameter over sheathing | mm | 24.2 | 24.2 | 25.1 | 26.7 | 28.4 | 29.9 | 31.3 | 33.2 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 30°C | A | l85 | l85 | 210 | 260 | 315 | 365 | 4l5 | 475 |

| Ambient temperature = 40°C Solar radiation = IOOOw/m2 Wind speed = lm/s | A | 155 | 155 | l85 | 230 | 280 | 325 | 370 | 425 |

| Earth fault current carrying capacity of metallic screen at -1 second ( 1 core ) | kA | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Messenger – Galvanized steel wire | |||||||||

| Stranding | No./mm | 7/2.0 | 19/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 |

| Direction of the outermost layer | Righthand (Z) | ||||||||

| Overall diameter | mm | 6 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Completed cable | |||||||||

| Approx. overall diameter | mm | 54.4 | 58.4 | 60.1 | 63.4 | 66.8 | 69.8 | 72.6 | 76.4 |

| Approx. weight of cable | kg/km | l890 | 2190 | 2320 | 2610 | 2960 | 3260 | 3590 | 4060 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 500 | 500 | 250 | 250 |

AL/XLPE/SCW/HDPE AERIAL BUNDLED CABLES AS/NZS 3599.1 (Heavy Duty Screen) 6.35/11 (12) kV

| Phase conductor | |||||||||

| Nominal cross.sectional area | mm2 | 35 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 7 | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 |

| Minimum thickness of insulation screen | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| No. and diameter of metallic screening approx. of copper wire | no./mm | 40/0.85 | 40/0.85 | 23/l.35 | 32/l.35 | 38/l.35 | 38/l.35 | 38/l.35 | 38/l.35 |

| Nominal thickness of outer sheath | mm | l.8 | l.8 | l.8 | l.8 | l.8 | l.8 | l.8 | 1.9 |

| Nominal diameter over sheathing | mm | 24.2 | 24.2 | 26.1 | 27.7 | 29.4 | 30.9 | 32.3 | 34.2 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 30°C | A | l85 | l85 | 210 | 260 | 315 | 365 | 4l5 | 475 |

| Ambient temperature = 40°C Solar radiation = I000w/m2 Wind speed = lm/s | A | 155 | 155 | l85 | 230 | 280 | 325 | 370 | 425 |

| Earth fault current carrying capacity of metallic screen at -1 second ( 1 Core ) | kA | 3.3 * | 3.3 * | 4.8* | 6.8* | 8 | 8 | 8 | 8 |

| Messenger – Galvanized steel wire | |||||||||

| Stranding | No./mm | 7/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 |

| Direction of the outermost layer | Right-hand (Z) | ||||||||

| Overall diameter | mm | 6 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Completed cable | |||||||||

| Approx. overall diameter | mm | 54.4 | 58.4 | 62.1 | 65.4 | 68.8 | 7l.8 | 74.6 | 78.4 |

| Approx. weight of cable | kg/km | 2150 | 2440 | 2880 | 3540 | 4l30 | 4440 | 4770 | 5240 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 500 | 500 | 250 | 250 |

The screen earth fault current rating is limited by the short circuit current rating of conductor.

AL/XLPE/SCW/HDPE AERIAL BUNDLED CABLES AS/NZS 3599.1 (Light Duty Screen) 12.7/22 (24) kV

| Phase conductor | |||||||||

| Nominal cross-sectional area | mm2 | 35 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 7 | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Minimum thickness of insulation screen | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| No. and diameter of metallic screening approx. of copper wire | no./mm | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 | 24/0.85 |

| Nominal thickness of outer sheath | mm | l.8 | l.8 | l.8 | l.8 | 1.9 | 1.9 | 2 | 2 |

| Nominal diameter over sheathing | mm | 28.4 | 28.4 | 29.3 | 30.9 | 32.8 | 34.3 | 35.9 | 37.6 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 30°C | A | 170 | 170 | 205 | 260 | 315 | 360 | 4l0 | 470 |

| Ambient temperature = 40°C Solar radiation = IOOOw/m2 Wind speed = lm/s | A | 150 | 150 | l85 | 230 | 280 | 320 | 365 | 4l5 |

| Earth fault current carrying capacity of metallic screen at -1 second ( 1 Core ) | kA | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Messenger – Galvanized steel wire | |||||||||

| Stranding | No./mm | 7/2.0 | 19/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 |

| Direction of the outermost layer | Righthand (Z) | ||||||||

| Overall diameter | mm | 6 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Completed cable | |||||||||

| Approx. overall diameter | mm | 62.8 | 66.8 | 68.5 | 7l.8 | 75.6 | 78.6 | 8l.8 | 85.2 |

| Approx. weight of cable | kg/km | 2340 | 2640 | 2780 | 3100 | 3510 | 3850 | 4240 | 47l0 |

| Packing length | m/drum | 500 | 500 | 500 | 250 | 250 | 250 | 250 | 250 |

AL/XLPE/SCW/HDPE AERIAL BUNDLED CABLES AS/NZS 3599.1 (Heavy Duty Screen) 12.7/22 (24) kV

| Phase conductor | |||||||||

| Nominal cross.sectional area | mm2 | 35 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 7 | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Minimum thickness of insulation screen | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| No. and diameter of metallic screening approx. of copper wire | no./mm | 40/0.85 | 40/0.85 | 23/l.35 | 32/l.35 | 38/l.35 | 38/l.35 | 38/l.35 | 38/l.35 |

| Nominal thickness of outer sheath | mm | l.8 | l.8 | l.8 | l.8 | 1.9 | 1.9 | 2 | 2 |

| Nominal diameter over sheathing | mm | 28.4 | 28.4 | 30.3 | 31.9 | 33.8 | 35.3 | 36.9 | 38.6 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 30°C | A | 170 | 170 | 205 | 260 | 315 | 360 | 4l0 | 470 |

| Ambient temperature = 40°C Solar radiation = I000w/m2 Wind speed = lm/s | A | 150 | 150 | l85 | 230 | 280 | 320 | 365 | 4l5 |

| Earth fault current carrying capacity of metallic screen at -1 second ( 1 Core ) | kA | 3.3 * | 3.3 * | 4.8* | 6.8* | 8 | 8 | 8 | 8 |

| Messenger – Galvanized steel wire | |||||||||

| Stranding | No./mm | 7/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 | l9/2.0 |

| Direction of the outermost layer | Right-hand (Z) | ||||||||

| Overall diameter | mm | 6 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Completed cable | |||||||||

| Approx. overall diameter | mm | 62.8 | 66.8 | 70.5 | 73.8 | 77.6 | 80.6 | 83.8 | 87.2 |

| Approx. weight of cable | kg/km | 2600 | 2900 | 3350 | 4030 | 4680 | 5020 | 54l0 | 5880 |

| Packing length | m/drum | 500 | 500 | 500 | 250 | 250 | 250 | 250 | 250 |

The screen earth fault current rating is limited by the short circuit current rating of conductor.

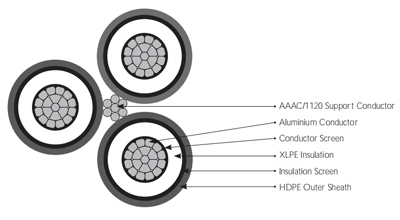

AL/XLPE INSULATED, PE OUTER SHEATHED AERIAL BUNDLED CABLES AL/XLPE/HDPE AERIAL CABLES, MEDIUM VOLTAGE AS/NZS 3599.2

DESCRIPTION

Circular compacted stranded aluminium conductor; XLPE insulated, copper wire screened and HDPE outer sheathed cable.The three XLPE insulated and copper wire screened single core cables are bundled around the AAAC/1120 support conductor in a right hand lay.

CONSTRUCTION

-

Conductor Phase conductors are circular compacted stranded H68 aluminium to BS2627.

-

Conductor screen Extruded layer of semi-conductive compound.

-

Insulation XLPE (cross-linked polyethylene) rated at 90°C.

-

Insulation screen Extruded layer of semi-conductive cross-linked compound.

-

Outer sheath Extruded layer of semi-conductive HDPE compound colour The outer sheath shallbe printed with figures l ONE, 2TWO, 3 THREE which corresponding to the three different phases.

-

Support conductorThe support conductor shall comprise a compacted all aluminium alloy conductor (AAAC/1120 ).

-

Assembly The three XLPE insulated cores shall be bundled around theAAAC/ll20 support conductor in a right hand (Z) lay.

AERIAL BUNDLED CABLES AL/XLPE/HDPE AS/NZS 3599.2 6.35/11 (12) kV

| Phase conductor | ||||||||

| Nominal cross-sectional area | mm2 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 | 3.4 |

| Nominal thickness of cross-linked screen layer | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Nominal thickness of semi-conductive HDPE layer | mm | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 40°C Solar radiation = I000w/m2 Wind speed = lm/s | A | 165 | 200 | 245 | 300 | 345 | 390 | 450 |

| Messenger – AAAC 1120 | ||||||||

| Stranding | No./mm | 7/5.0 | 7/5.0 | 7/5.0 | 7/5.0 | 19/3.65 | l9/3.65 | l9/3.65 |

| Direction of the outermost layer | Righthand (Z) | |||||||

| Overall diameter | mm | l4.3 | l4.3 | l4.3 | l4.3 | 17.3 | 17.3 | 17.3 |

| Completed cable | ||||||||

| Approx. overall diameter | mm | 52.2 | 53.5 | 56.7 | 60.2 | 66.2 | 69 | 72.4 |

| Approx. weight of cable | kg/km | l470 | l580 | l850 | 2l80 | 2640 | 2960 | 3380 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 500 | 500 | 250 |

AERIAL BUNDLED CABLES AL/XLPE/HDPE AS/NZS 3599.2 12.7/22 (24) kV

| Phase conductor | ||||||||

| Nominal cross.sectional area | mm2 | 35 | 50 | 70 | 95 | 120 | 150 | l85 |

| Number of cores | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Minimum number of wires | 6 | 6 | 12 | 15 | l8 | l8 | 30 | |

| Nominal diameter of conductor | mm | 7 | 8.l | 9.7 | 11.5 | 12.9 | l4.3 | 16.1 |

| Minimum thickness of conductor screen | mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nominal thickness of XLPE insulation | mm | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Nominal thickness of cross-linked screen layer | mm | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Nominal thickness of semi-conductive HDPE layer | mm | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Max. dc resistance at 20°C | ohm/km | 0.868 | 0.64l | 0.443 | 0.32 | 0.253 | 0.206 | 0.l64 |

| Current rating at Ambient temperature = 40°C Solar radiation = I000w/m2 Wind speed = lm/s | A | 165 | 195 | 245 | 295 | 340 | 385 | 440 |

| Messenger – AAAC 1120 | ||||||||

| Stranding | No./mm | 7/5.0 | 7/5.0 | 7/5.0 | 7/5.0 | l9/3.65 | l9/3.65 | l9/3.65 |

| Direction of the outermost layer | Right-hand (Z) | |||||||

| Overall diameter | mm | l4.3 | l4.3 | l4.3 | l4.3 | 17.3 | 17.3 | 17.3 |

| Completed cable | ||||||||

| Approx. overall diameter | mm | 60.6 | 61.9 | 65.1 | 68.6 | 74.6 | 77.4 | 80.8 |

| Approx. weight of cable | kg/km | l890 | 2000 | 2300 | 2670 | 3160 | 3500 | 3950 |

| Packing length | m/drum | 500 | 500 | 500 | 500 | 250 | 250 | 250 |