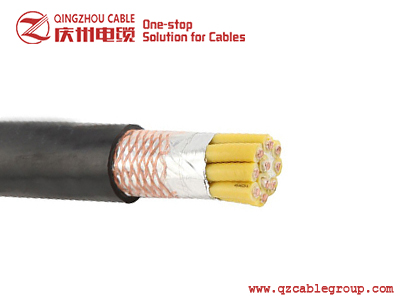

PVC insulated control cable

This product is used for electrical appliance and instrument connecting cables in power distribution equipment with AC rated voltage of 450/750V and below.

Its mechanical and physical properties and electrical performance meet the requirements of GB/T9330-2008 "Plastic Insulated Control Cable.

Operating characteristics

Cable laying temperature: ≥0°C

Long-term allowable operating temperature of cable conductor: 70°C

Minimum permissible bending radius:

For unarmored cables, should be no less than six times of cable outer diameter;

For armored or copper belt shield structure cables, should be not less than 12 times of cable outer diameter;

For flexible cable with shield structure, shoud be less than six times of cable outer diameter.

Finished cable can bear AC 5HZ, 3KV, 5min withstand test without breakdown.

Conductor DC resistance meets the requirements of national standard GB/T3956-2008 “Cable Conductor” and international standard IEC60228.

Cable Models, Names and Laying Occasions

|

Model |

Name |

Laying Occasion |

|

KVV |

Copper core PVC insulated PVC sheathed control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions. |

|

KVVP |

Copper core PVC insulated PVC sheathed braid shield control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions requiring shielding. |

|

KVVP2 |

Copper core PVC insulated PVC sheathed braid shield control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions requiring shielding. |

|

KVV22 |

Copper core PVC insulated PVC sheathed copper belt shield control cable |

Laid indoors, and in cable trenches, pipelines, direct-buring and other fixed places capable of bearing large mechanical force. |

|

KVV32 |

Copper core PVC insulated PVC sheathed steel tape armored control cable |

Laid indoors, and in cable trenches, pipelines, vertical shafts and other fixed places capable of bearing large mechanical force. |

|

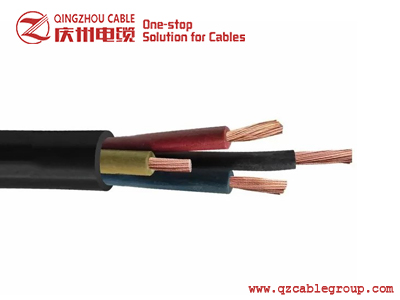

KVVR |

Copper core PVC insulated PVC sheathed, fine steel wire armored control cable |

Laid indoors in occasions requiring movement and flexibility. |

|

KVVRP |

Copper core PVC insulated PVC sheathed flexible control cable |

Laid indoors in occasions requiring movement, flexibility and shielding. |

|

KVVP2-22 |

Copper core PVC insulated PVC sheathed copper belt shield steel tape armored control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions capable of bearing large mechanical force and requiring shielding. |

Range of production

|

Model |

Rated voltage (V) |

Conductor nominal cross sectional area (mm2) |

|||||||

|

|

0.75 |

1.0 |

1.5 |

2.5 |

4 |

6 |

10 |

||

|

KV |

450/750 |

– |

2-61 |

2-14 |

2-10 |

||||

|

KVVP |

|||||||||

|

KVVP2 |

|

4-61 |

4-14 |

4-10 |

|||||

|

KVV22 |

– |

7-61 |

4-61 |

4-14 |

4-10 |

||||

|

KVVP2-22 |

|||||||||

|

KVV32 |

– |

19-61 |

7-61 |

4-14 |

4-10 |

||||

|

KVVR |

|

4-61 |

– |

– |

|||||

|

KVVRP |

4-61 |

4-48 |

– |

– |

|||||

Notes: The recommended number of cores is: 2, 3, 4, 5, 7, 8, 10, 12, 14, 16, 19, 24, 27, 37, 44, 48, 52 and 61

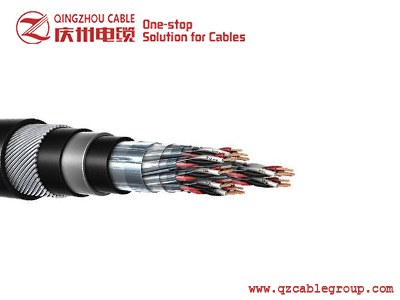

XLPE Insulated Control Cable

This product is used for electrical appliance and instrument connecting cables in power distribution equipment with AC rated voltage of 450/750 V and below.

Its mechanical and physical properties and electrical performance meet the requirements in GB/T9330-2008 "XLPE Insulated Control Cable”.

Operating characteristics and electrical performance

Cable laying temperature: ≥0°C

Long-term allowable operating temperature of cable conductor: 90°C

Minimum permissible bending radius:

For unarmored cables, should be no less than 6 times of cable outer diameter;

For armored or copper belt shield structure cables, should be not less than 12 times of cable outer diameter;

For flexible cable with shield structure, shoud be less than six times of cable outer diameter.

Finished cable can bear AC 50HZ, 3 KV, 5min withstand test without breakdown.

Conductor DC resistance meets the requirements of national standard GB/T3956-2008 “Cable Conductor” and international standard IEC60228.

Models, Names and Laying Occasions of XLPE Insulated Control Cable

|

Model |

Name |

Laying Occasion |

|

KYJV |

Copper core XLPE insulated PVC sheathed control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions. |

|

KYJVP |

Copper core XLPE insulated PVC sheathed braid shield control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions requiring shielding. |

|

KYJVP2 |

Copper core XLPE insulated PVC sheathed copper belt shield control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions requiring shielding. |

|

KYJV22 |

Copper core XLPE insulated PVC sheathed steel tape armored control cable |

Laid indoors, and in cable trenches, pipelines, direct-buring and other fixed places capable of bearing large mechanical force. |

|

KYJV32 |

KYJV32 Copper core XLPE insulated PVC sheathed fine steel wire armored control cable |

Laid indoors, and in cable trenches, pipelines, vertical shafts and other fixed places capable of bearing large mechanical force. |

|

KYJVR |

Copper core XLPE insulated PVC sheathed flexible control cable |

Laid indoors in occasions requiring movement and flexibility. |

|

KYJVRP |

Copper core XLPE insulated PVC sheathed braid shielding control cable |

Laid indoors in occasions requiring movement, flexibility and shielding. |

|

KYJVP2-22 |

Copper core XLPE insulated PVC sheathed steel tape shielded steel plate armored control cable |

Laid indoors, and in cable trenches, pipelines and other fixed occasions capable of bearing large mechanical force and requiring shielding. |

Range of production

|

Model |

Rated voltage (V) |

Conductor nominal cross sectional area (mm2) |

|||||||

|

|

0.75 |

1.0 |

1.5 |

2.5 |

4 |

6 |

10 |

||

|

KYJV |

45O/750 |

– |

2-61 |

2-14 |

2-10 |

||||

|

KYJVP |

|||||||||

|

KYJP2 |

|

4-61 |

4-14 |

4-10 |

|||||

|

KYJV22 |

– |

7-61 |

4-61 |

4-14 |

4-10 |

||||

|

KYJVP2-22 |

|||||||||

|

KYJV32 |

– |

19-61 |

7-61 |

4-14 |

4-10 |

||||

|

KYJVR |

|

4-61 |

– |

– |

|||||

|

KYJVRP |

4-61 |

4-48 |

– |

– |

|||||

Notes: The recommended number of cores is: 2, 3, 4, 5, 7, 8, 10, 12, 14, 16, 19, 24, 27, 37, 44, 48, 52 and 61.

DIMENSIONS & WEIGHTS – SIZE 1.5 mm2 (Stranded)

CU/XLPE/SWA/PVC – BS 5467 CU CONDUCTOR, XLPE INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | kg/km | mtrs |

| 7 | 0.6 | 0.8 | 0.9 | 1.4 | 16.0 | 435 | 1000 | 1000 |

| 9 | 0.6 | 0.8 | 1.25 | 1.5 | 18.5 | 645 | 1000 | 1000 |

| 12 | 0.6 | 0.8 | 1.25 | 1.5 | 19.5 | 740 | 1000 | 1000 |

| 19 | 0.6 | 0.8 | 1.25 | 1.6 | 22.5 | 975 | 1000 | 1000 |

| 21 | 0.6 | 1.0 | 1.6 | 1.7 | 24.5 | 1220 | 1000 | 1000 |

| 27 | 0.6 | 1.0 | 1.6 | 1.7 | 27.0 | 1450 | 1000 | 1000 |

| 37 | 0.6 | 1.0 | 1.6 | 1.7 | 29.5 | 1740 | 1000 | 1000 |

| 48 | 0.6 | 1.0 | 1.6 | 1.8 | 33.5 | 2100 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 1.5 mm2(Stranded)

CU/XLPE/PVC – IEC-60502 Part 1 CU CONDUCTOR, XLPE INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Cable Weight | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | kg/km |

| 6 | 0.7 | 1.8 | 13.0 | 230 | 1000 |

| 7 | 0.7 | 1.8 | 13.0 | 245 | 1000 |

| 9 | 0.7 | 1.8 | 15.0 | 315 | 1000 |

| 12 | 0.7 | 1.8 | 17.0 | 375 | 1000 |

| 19 | 0.7 | 1.8 | 19.0 | 535 | 1000 |

| 21 | 0.7 | 1.8 | 20.0 | 585 | 1000 |

| 27 | 0.7 | 1.8 | 23.0 | 720 | 1000 |

| 37 | 0.7 | 1.8 | 25.0 | 940 | 1000 |

| 48 | 0.7 | 1.8 | 29.0 | 1185 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 2.5 mm2 (Stranded)

CU/XLPE/SWA/PVC – BS 5467 CU CONDUCTOR, XLPE INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.7 | 0.8 | 0.9 | 1.4 | 17.5 | 515 | 1000 | 1000 |

| 7 | 0.7 | 0.8 | 0.9 | 1.4 | 17.5 | 540 | 1000 | 1000 |

| 9 | 0.7 | 0.8 | 1.25 | 1.6 | 20.0 | 795 | 1000 | 1000 |

| 12 | 0.7 | 0.8 | 1.25 | 1.6 | 21.5 | 930 | 1000 | 1000 |

| 19 | 0.7 | 1.0 | 1.6 | 1.7 | 26.0 | 1415 | 1000 | 1000 |

| 21 | 0.7 | 1.0 | 1.6 | 1.8 | 27.0 | 1525 | 1000 | 1000 |

| 27 | 0.7 | 1.0 | 1.6 | 1.8 | 30.0 | 1815 | 1000 | 1000 |

| 37 | 0.7 | 1.0 | 1.6 | 1.8 | 33.0 | 2225 | 500 | 1000 |

| 48 | 0.7 | 1.2 | 2 | 2.0 | 38.5 | 3040 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 2.5 mm2 (Stranded)

CU/XLPE/PVC – IEC-60502 Part 1 CU CONDUCTOR, XLPE INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.7 | 1.8 | 14.0 | 305 | 1000 | 1000 |

| 7 | 0.7 | 1.8 | 14.0 | 325 | 1000 | 1000 |

| 9 | 0.7 | 1.8 | 17.0 | 420 | 1000 | 1000 |

| 12 | 0.7 | 1.8 | 18.0 | 510 | 1000 | 1000 |

| 19 | 0.7 | 1.8 | 21.0 | 740 | 1000 | 1000 |

| 21 | 0.7 | 1.8 | 22.0 | 815 | 1000 | 1000 |

| 27 | 0.7 | 1.8 | 25.0 | 1010 | 1000 | 1000 |

| 37 | 0.7 | 1.8 | 28.0 | 1330 | 1000 | 1000 |

| 48 | 0.7 | 1.9 | 32.0 | 1700 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 4 mm2 (Stranded)

CU/XLPE/SWA/PVC – BS 5467 CU CONDUCTOR, XLPE INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.7 | 0.8 | 1.25 | 1.5 | 19.0 | 770 | 1000 | 1000 |

| 7 | 0.7 | 0.8 | 1.25 | 1.5 | 19 | 805 | 1000 | 1000 |

| 9 | 0.7 | 1.0 | 1.6 | 1.6 | 23.0 | 1175 | 1000 | 1000 |

| 12 | 0.7 | 1.0 | 1.6 | 1.6 | 25 | 1355 | 1000 | 1000 |

| 19 | 0.7 | 1.0 | 1.6 | 1.7 | 28.5 | 1815 | 1000 | 1000 |

| 21 | 0.7 | 1.0 | 1.6 | 1.9 | 30 | 1975 | 1000 | 1000 |

| 27 | 0.7 | 1.0 | 1.6 | 1.9 | 33.5 | 2375 | 500 | 1000 |

| 37 | 0.7 | 1.2 | 2 | 2.0 | 38 | 3265 | 500 | 1000 |

| 48 | 0.7 | 1.2 | 2 | 2.1 | 43 | 3990 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 4 mm2 (Stranded)

CU/XLPE/PVC – IEC-60502 Part 1 CU CONDUCTOR, XLPE INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.7 | 1.8 | 16.0 | 415 | 1000 | 1000 |

| 7 | 0.7 | 1.8 | 16.0 | 450 | 1000 | 1000 |

| 9 | 0.7 | 1.8 | 19.0 | 580 | 1000 | 1000 |

| 12 | 0.7 | 1.8 | 20.0 | 715 | 1000 | 1000 |

| 19 | 0.7 | 1.8 | 24.0 | 1050 | 1000 | 1000 |

| 21 | 0.7 | 1.8 | 25.0 | 1160 | 1000 | 1000 |

| 27 | 0.7 | 1.8 | 28.0 | 1450 | 1000 | 1000 |

| 37 | 0.7 | 1.9 | 32.0 | 1930 | 500 | 1000 |

| 48 | 0.7 | 2.1 | 37.0 | 2490 | 500 | 1000 |

PVC INSULATED CONTROL CABLES CONFORMING TO IEC 60502-1 AND BS 6346 600/1000 VOLTS

DIMENSIONS & WEIGHTS – SIZE 1.5 mm2 (Stranded)

CU/PVC/SWA/PVC – BS 6346 CU CONDUCTOR, PVC INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.6 | 0.8 | 0.9 | 1.4 | 17.5 | 470 | 1000 | 1000 |

| 7 | 0.6 | 0.8 | 0.9 | 1.4 | 17.5 | 490 | 1000 | 1000 |

| 9 | 0.6 | 0.8 | 1.25 | 1.5 | 20.0 | 730 | 1000 | 1000 |

| 12 | 0.6 | 0.8 | 1.25 | 1.5 | 21.5 | 835 | 1000 | 1000 |

| 19 | 0.6 | 0.8 | 1.25 | 1.6 | 24.5 | 1105 | 1000 | 1000 |

| 21 | 0.6 | 1.0 | 1.6 | 1.7 | 27.0 | 1380 | 1000 | 1000 |

| 27 | 0.6 | 1.0 | 1.6 | 1.7 | 29.5 | 1635 | 1000 | 1000 |

| 37 | 0.6 | 1.0 | 1.6 | 1.8 | 32.5 | 1995 | 1000 | 1000 |

| 48 | 0.6 | 1.0 | 1.6 | 1.9 | 36.0 | 2430 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 1.5 mm2 (Stranded)

CU/PVC/PVC – IEC-60502 Part 1 CU CONDUCTOR, PVC INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.8 | 1.8 | 14.5 | 270 | 1000 | 1000 |

| 7 | 0.8 | 1.8 | 14.5 | 285 | 1000 | 1000 |

| 9 | 0.8 | 1.8 | 16.5 | 375 | 1000 | 1000 |

| 12 | 0.8 | 1.8 | 18.0 | 445 | 1000 | 1000 |

| 19 | 0.8 | 1.8 | 21.0 | 640 | 1000 | 1000 |

| 21 | 0.8 | 1.8 | 22.0 | 705 | 1000 | 1000 |

| 27 | 0.8 | 1.8 | 24.5 | 870 | 1000 | 1000 |

| 37 | 0.8 | 1.8 | 27.0 | 1140 | 1000 | 1000 |

| 48 | 0.8 | 1.9 | 31.0 | 1460 | 1000 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 2.5 mm2 (Stranded)

CU/PVC/SWA/PVC – BS 6346 CU CONDUCTOR, PVC INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | mtrs |

| 6 | 0.7 | 0.8 | 1.25 | 1.5 | 19.0 | 670 | 1000 |

| 7 | 0.7 | 0.8 | 1.25 | 1.5 | 19.0 | 700 | 1000 |

| 9 | 0.7 | 0.8 | 1.25 | 1.6 | 21.5 | 890 | 1000 |

| 12 | 0.7 | 0.8 | 1.25 | 1.6 | 23.5 | 1030 | 1000 |

| 19 | 0.7 | 1.0 | 1.6 | 1.7 | 28.0 | 1575 | 1000 |

| 21 | 0.7 | 1.0 | 1.6 | 1.8 | 29.0 | 1700 | 1000 |

| 27 | 0.7 | 1.0 | 1.6 | 1.8 | 32.0 | 2025 | 1000 |

| 37 | 0.7 | 1.0 | 1.6 | 1.9 | 35.5 | 2525 | 500 |

| 48 | 0.7 | 1.2 | 2.0 | 2.1 | 41.0 | 3445 | 500 |

DIMENSIONS & WEIGHTS – SIZE 2.5 mm2 (Stranded)

CU/PVC/PVC – IEC-60502 Part 1 COPPER CONDUCTOR, PVC INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight for CU Cable | Approx. Cable Weight for AL Cable | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | kg/km | mtrs |

| 6 | 0.8 | 1.8 | 15.5 | 345 | 1000 | 1000 |

| 7 | 0.8 | 1.8 | 15.5 | 375 | 1000 | 1000 |

| 9 | 0.8 | 1.8 | 18.0 | 495 | 1000 | 1000 |

| 12 | 0.8 | 1.8 | 20.0 | 590 | 1000 | 1000 |

| 19 | 0.8 | 1.8 | 23.0 | 865 | 1000 | 1000 |

| 21 | 0.8 | 1.8 | 24.0 | 955 | 1000 | 1000 |

| 27 | 0.8 | 1.8 | 27.0 | 1185 | 1000 | 1000 |

| 37 | 0.8 | 1.9 | 30.5 | 1575 | 1000 | 1000 |

| 48 | 0.8 | 2.0 | 34.5 | 2020 | 500 | 1000 |

DIMENSIONS & WEIGHTS – SIZE 4 mm2 (Stranded)

CU/PVC/SWA/PVC – BS 6346 COPPER CONDUCTOR, PVC INSULATED, STEEL WIRE ARMOURED, PVC SHEATHED

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Extruded Bedding | Nominal Diameter of Armour Wire | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight | Packing Length (Standard) |

| mm² | mm | mm | mm | mm | mm | kg/km | mtrs |

| 6 | 0.8 | 0.8 | 1.25 | 1.6 | 22.0 | 915 | 1000 |

| 7 | 0.8 | 0.8 | 1.25 | 1.6 | 22.0 | 960 | 1000 |

| 9 | 0.8 | 1.0 | 1.6 | 1.7 | 26.5 | 1385 | 1000 |

| 12 | 0.8 | 1.0 | 1.6 | 1.7 | 28.5 | 1610 | 1000 |

| 19 | 0.8 | 1.0 | 1.6 | 1.8 | 32.5 | 2160 | 500 |

| 21 | 0.8 | 1.2 | 2.0 | 2.0 | 35.5 | 2645 | 500 |

| 27 | 0.8 | 1.2 | 2.0 | 2.0 | 39.5 | 3150 | 500 |

| 37 | 0.8 | 1.2 | 2.0 | 2.1 | 43.5 | 3930 | 500 |

| 48 | 0.8 | 1.2 | 2.0 | 2.2 | 49.0 | 4825 | 500 |

DIMENSIONS & WEIGHTS – SIZE 4 mm2 (Stranded)

CU/PVC/PVC – IEC-60502 Part 1 CU CONDUCTOR, PVC INSULATED, PVC SHEATHED (UNARMOURED)

| Nominal Area of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Outer Sheath | Approx. Overall Diameter | Approx. Cable Weight | Packing Length (Standard) |

| mm² | mm | mm | mm | kg/km | mtrs |

| 6 | 1.0 | 1.8 | 18.5 | 510 | 1000 |

| 7 | 1.0 | 1.8 | 18.5 | 555 | 1000 |

| 9 | 1.0 | 1.8 | 21.5 | 735 | 1000 |

| 12 | 1.0 | 1.8 | 23.5 | 885 | 1000 |

| 19 | 1.0 | 1.8 | 27.5 | 1305 | 1000 |

| 21 | 1.0 | 1.8 | 29.0 | 1445 | 1000 |

| 27 | 1.0 | 2.0 | 33.0 | 1830 | 500 |

| 37 | 1.0 | 2.1 | 37.0 | 2435 | 500 |

| 48 | 1.0 | 2.3 | 42.5 | 3140 | 500 |