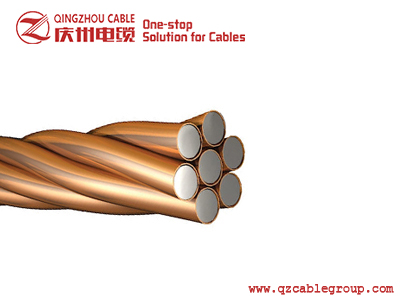

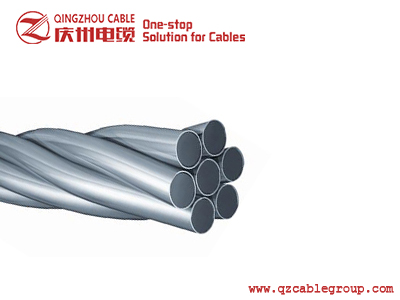

Application

zinc–5 % aluminummischmetal (Zn–5Al–MM) alloy-coated, steel core wire for use in Overhead Electrical Conductors. ACSS ACSS/TW The high temperature low sag solution

Specification

ASTM B802 803 958

Class

Round, high strength, extra-high-strength, and ultra-high-strength, Class A B C coated

Features

operates continuously at high temperatures up to 250°C, with proper steel coating, ensuring maximum utilization and performance; standard coating for high temperature operation is a Zn-5% Al Mischmetal coating so that customers can take full advantage of the 250°C

continuous operating temperature rating. Galvanized coatings are rated only 180°C for continuous operation.

ASTM B802-02-American Society for Testing and Materials

|

Specified Diameter of Coated Wire,mm

|

Area Density of Coating, min, oz/ft2 of Uncoated Wire Surface

|

|

|

Class A

|

Class B

|

Class C

|

|

0.0500 to 0.0599, incl

|

0.60

|

1.20

|

1.80

|

|

0.0600 to 0.0749, incl

|

0.65

|

1.30

|

1.95

|

|

0.0750 to 0.0899, incl

|

0.70

|

1.40

|

2.10

|

|

0.0900 to 0.1039, incl

|

0.75

|

1.50

|

2.25

|

|

0.1040 to 0.1199, incl

|

0.80

|

1.60

|

2.40

|

|

0.1200 to 0.1399, incl

|

0.85

|

1.70

|

2.55

|

|

0.1400 to 0.1799, incl

|

0.90

|

1.80

|

2.70

|

|

0.1800 to 0.1900, incl

|

1.00

|

2.00

|

3.00

|

MORE

TABLE 5 Tensile Requirements

|

Specified Diameter, in.

|

Stress at 1 % Extension, min, Ksi

|

Ultimate Tensile Strength, min, MPa

|

Elongation in 250 mm, min, %

|

|

Class A

|

Class B

|

Class C

|

Class A

|

Class B

|

Class C

|

Class A

|

Class B

|

Class C

|

|

1.60 to 2.30, incl

|

190

|

180

|

170

|

210

|

200

|

190

|

3.0

|

3.0

|

3.0

|

|

Over 2.30 to 3.05, incl

|

185

|

175

|

165

|

205

|

195

|

185

|

3.5

|

3.0

|

3.0

|

|

Over 3.05 to 3.60, incl

|

180

|

170

|

160

|

205

|

195

|

185

|

4.0

|

3.0

|

3.0

|

|

Over 3.60 to 4.80, incl

|

170

|

160

|

155

|

200

|

185

|

180

|

4.0

|

4.0

|

4.0

|

ASTM B802-10 Zn-5Al-MM Alloy Coating (Metric)

|

Specified Diameter of Coated Wire, mm

|

Area Density of Coating, min.g/m2 of Uncoated Wire Surface

|

|

|

Class A

|

Class C

|

|

1.27 to 1.52, incl

|

183

|

549

|

|

1.53 to 1.90, incl

|

198

|

594

|

|

1.91 to 2.28, incl

|

214

|

642

|

|

2.29 to 2.64, incl

|

229

|

687

|

|

2.65 to 3.04, incl

|

244

|

732

|

|

3.05 to 3.55, incl

|

259

|

777

|

|

3.56 to 4.57, incl

|

274

|

822

|

MORE

Normal Grade Tensile Requirements (Metric)

|

Specified Diameter, mm

|

Stress at 1 % Extension, min, MPa

|

Ultimate Tensile Strength, min, MPa

|

Elongation in 250 mm, min, %

|

|

|

Class A

|

Class C

|

Class A

|

Class C

|

Class A

|

Class C

|

|

1.27 to 2.28, incl

|

1310

|

1170

|

1450

|

1310

|

3.0

|

3.0

|

|

2.29 to 3.04, incl

|

1280

|

1140

|

1410

|

1280

|

3.5

|

3.0

|

|

3.05 to 3.55, incl

|

1240

|

1100

|

1410

|

1280

|

4.0

|

3.0

|

|

3.56 to 4.82, incl

|

1170

|

1070

|

1380

|

1240

|

4.0

|

4.0

|

ASTM B803 Tensile Requirements

|

Specified Diameter

|

Stress at 1 % Extension, min

|

Ultimate Tensile Strength, min

|

Elongation in 10 in. or 250 mm,

|

|

in.

|

mm

|

ksi

|

MPa

|

ksi

|

MPa

|

min %

|

|

0.0500 to 0.0899, incl

|

1.270 to 2.283, incl

|

210

|

1450

|

235

|

1620

|

3.0

|

|

0.0900 to 0.1199, incl

|

2.286 to 3.045, incl

|

205

|

1410

|

230

|

1590

|

3.0

|

|

0.1200 to 0.1399, incl

|

3.048 to 3.553, incl

|

200

|

1380

|

225

|

1550

|

3.5

|

|

0.1400 to 0.1900, incl

|

3.556 to 4.823, incl

|

195

|

1340

|

220

|

1520

|

3.5

|

ASTM B958-Grade 4 Extra-High-Strength Tensile Requirements (Metric)

|

Specified Diameter, mm

|

Stress at 1% Extension,

|

Ultimate Tensile Strength,

|

Elongation in 250 mm, min %

|

|

|

min, MPa

|

min, MPa

|

|

|

1.27 to 2.28, incl

|

1550

|

1825

|

3.0

|

|

2.29 to 3.04, incl

|

1515

|

1790

|

3.0

|

|

3.05 to 3.55, incl

|

1480

|

1760

|

3.5

|

|

3.56 to 4.82, incl

|

1450

|

1725

|

3.5

|

Grade 5 Ultra-High-Strength Tensile Requirements (Metric)

|

Specified Diameter, mm

|

Stress at 1% Extension,

|

Ultimate Tensile Strength,

|

Elongation in 250 mm, min %

|

|

|

min, MPa

|

min, MPa

|

|

|

1.27 to 2.28, incl

|

1580

|

1965

|

3.0

|

|

2.29 to 3.04, incl

|

1550

|

1900

|

3.0

|

|

3.05 to 3.55, incl

|

1515

|

1860

|

3.5

|

|

3.56 to 4.82, incl

|

1480

|

1825

|

3.5

|